Eco Solvent printers use eco-friendly weak solvent ink (Eco-Solvent Ink). Compared with traditional solvent inks, this ink has lower volatile organic compound (VOC) emissions, so it is more suitable for indoor use and has less impact on the environment and the health of operators.

Product Parameters

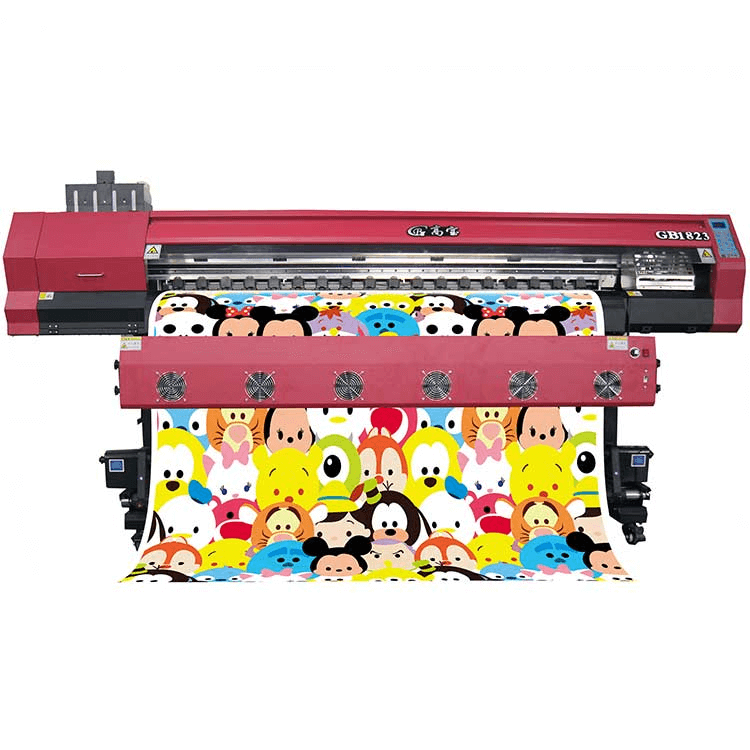

| Name | Inkjet Printer For Sublimation Printing |

| Model | GB1823 |

| Printing Head | Three Epson 5113 Heads |

| Width | 1.8M |

| Voltage | ac220v, 50-60hz |

| Power | 200-2500w |

| Feature | Easy handle / stable / long operation life |

| Speed/hr | 60m² per hour |

| Packing size | 3.25*0.95*0.95m |

| N.W | 300kgs |

Features

High-precision output: Eco Solvent printers are able to provide high-resolution image output, usually up to 1440dpi or higher, which makes the printed images delicate and colorful.

Outdoor weather resistance: Although Eco Solvent inks are not as weather-resistant as UV inks, their resistance to UV rays, wind and rain, and abrasion can be enhanced through appropriate post-processing (such as lamination), making them suitable for outdoor advertising and other application scenarios.

Wide material compatibility: Eco Solvent printers can print on a variety of flexible materials, including vinyl (Vinyl), photo paper, self-adhesive PP paper, etc., which makes it widely used in advertising, logo and sticker production.

Environmental protection: Due to the use of environmentally friendly weak solvent inks, Eco Solvent printers release fewer harmful substances during the printing process and have less impact on the environment.

Functions of Eco Solvent Printers

High-quality printing: Eco Solvent printers are able to provide high-quality image printing to meet the delicate needs of advertising, logo and artwork reproduction.

Multiple printing modes: Usually support multiple printing modes, including fast printing, high-quality printing, etc., to meet the needs of different application scenarios.

Automatic cleaning system: To prevent the print head from clogging, Eco Solvent printers are usually equipped with an automatic cleaning system, which can regularly clean the print head and keep it in good working condition.

Material compatibility: Able to identify and adapt to a variety of printing materials to ensure printing quality and effect.

Application fields of Eco Solvent printers

Advertising industry: Eco Solvent printers have a wide range of applications in the advertising industry, such as shopping mall light boxes, exhibition displays, car body advertisements, etc. Its high-quality image output and wide material compatibility make it the preferred tool for advertising production.

Logo production: In the field of logo production, Eco Solvent printers also perform well. It can print out a variety of logos, labels and stickers to meet the logo needs of commercial, industrial and public facilities.

Art reproduction: Due to its high precision and multiple color options, Eco Solvent printers are also suitable for the field of art reproduction. It can print high-quality artwork reproductions such as oil paintings, watercolors, etc., providing artists and collectors with a convenient way to reproduce.

Maintenance and care of Eco Solvent printers

In order to ensure the long-term stable operation and best printing effect of Eco Solvent printers, regular maintenance and care are required. Here are some common maintenance and care methods:

Clean the print head regularly: The print head is one of the core components of the printer, and its cleanliness directly affects the print quality. Therefore, it is necessary to regularly use a special cleaning fluid or the printer's own cleaning function to clean the print head to prevent clogging and damage.

Check the ink supply: Ink is one of the important consumables of the printer. It is necessary to check the remaining amount of ink regularly and replace or replenish it in time before the ink is exhausted. At the same time, pay attention to the quality and compatibility of the ink and ensure that the ink compatible with the printer is used.

Keep the printing environment clean: The working environment of the printer has a great impact on its performance and life. Therefore, it is necessary to keep the printing environment clean and dry to prevent dust and debris from entering the inside of the printer. In addition, avoid using the printer in a humid or high temperature environment.

Calibrate the printer regularly: In order to ensure the quality and accuracy of printing, the printer needs to be calibrated regularly. The calibration process usually includes steps such as adjusting the position of the print head and checking the print quality.

Check the power cord and connecting wires: Loose or damaged power cords and connecting wires may cause the printer to not work properly. Therefore, it is necessary to regularly check the connection of the power cord and connecting wires to ensure that they are firmly connected and not damaged.

Precautions when using Eco Solvent printer

Safe operation: When using Eco Solvent printer, you need to comply with relevant safety operation procedures, such as wearing protective glasses, gloves and other protective equipment, and avoid direct contact with ink and printing materials. At the same time, make sure that the printer is well grounded to prevent safety hazards such as static electricity.

Choose the right printing material: Different printing materials have a great impact on the performance and printing effect of the printer. Therefore, when choosing printing materials, you need to choose according to the compatibility of the printer and the application scenario. At the same time, pay attention to parameters such as material thickness, size and surface treatment to ensure that they meet the requirements of the printer.

Avoid long-term continuous printing: Long-term continuous printing may cause the printer to overheat or damage. Therefore, when using Eco Solvent printer, you need to avoid long-term continuous printing and arrange rest time appropriately. If you really need to print for a long time, you can consider using multiple printers to work alternately or using heat dissipation equipment to reduce the temperature of the printer.

Proper disposal of waste: When using Eco Solvent printer, some waste, such as waste ink, waste paper, etc., will be generated. These wastes need to be handled in accordance with local environmental protection regulations to avoid pollution to the environment. At the same time, you should also pay attention to the economical use of resources such as printing materials and ink.

.png)

.png)