1.Wider printing width: Compared to narrower ribbon printing machines, a 420mm Ribbon Sublimation Machine can print on wider ribbons, allowing for more design options and customization.

2.Versatility: A 420mm Ribbon Sublimation Machine can be used for a variety of applications, from printing logos or text onto ribbons for events, to printing branding or product information onto ribbons for packaging.

3.Customization: With a 420mm Ribbon Sublimation Machine, businesses can create their own unique designs and templates, allowing for greater customization and differentiation from competitors.

4.Time and cost savings: By using a Ribbon Sublimation Machine in-house, businesses can save time and money by avoiding outsourcing the printing process to a third-party vendor.

5.High-quality output: A high-quality 420mm Ribbon Sublimation Machine can offer fine printing resolution, resulting in sharp and clear designs and text on the ribbon.

| Model | 4290 |

| Diameter(mm) | 420 |

| width(mm) | 900 |

| Volatge | 110v 220v 380v |

| Power | 15kw |

| Temperature | 0-400℃ |

| Noise | 30qb |

| speed | 80-160m/h |

| weight | 900kg |

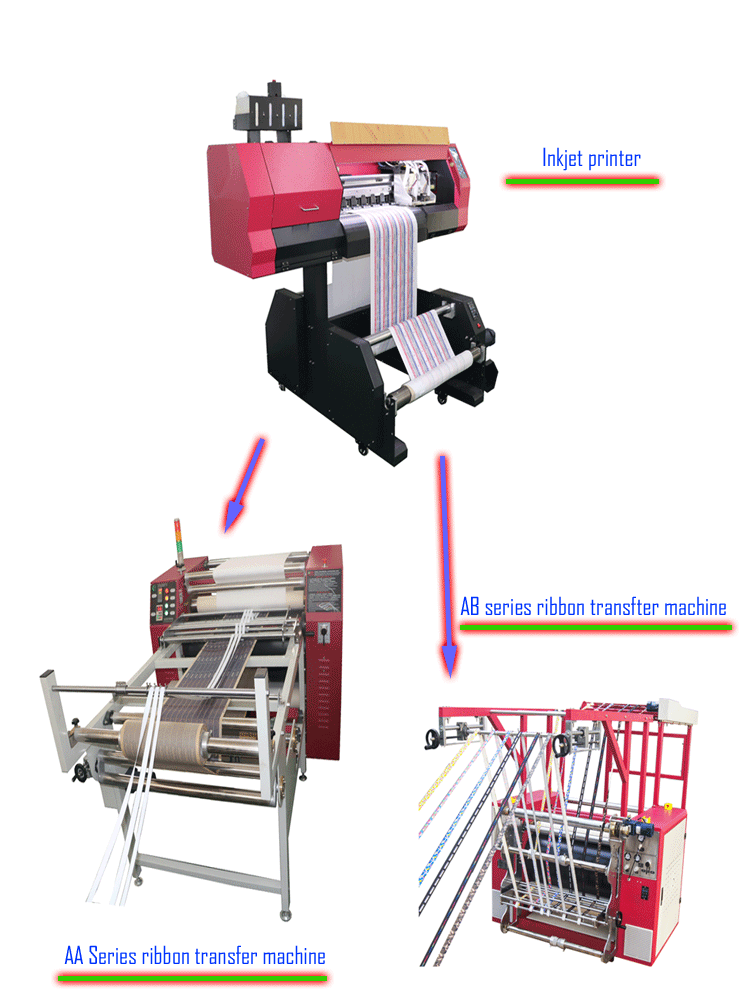

Printing Process

Product Details

Samples

Ribbon Sublimation Machine is a device used to transfer patterns or text onto materials such as fabric, plastic, metal, etc. It uses thermal transfer technology to print patterns or text on thermal paper, then stick the thermal paper on the material and use a heat press to heat it to transfer the pattern or text to the material.

First, print the pattern or text on thermal paper. Thermal paper is a special kind of paper that changes color when exposed to high temperatures.

Then, stick the thermal paper on the material.

Finally, use a heat press to heat the thermal paper to transfer the pattern or text to the material.

The patterns or text are clear and realistic.

Works on a variety of materials including fabrics, plastics, metals and more.

Simple operation and easy to use.

The price is relatively high.

It takes some skill to get good results.

Use high quality thermal paper for better results.

When heat pressing, make sure the thermal paper is in close contact with the material.

Do not heat press for too long to avoid damage to the material.

Hope the above information is helpful to you.