Product Description

This heat press sublimation roll automatic roll to roll printing machine adopts air-filled shaft technology for uniform printing on fabrics of different widths and shapes. This machine can be used to print a variety of fabrics, such as polyester, nylon and cotton. The machine is also equipped with a thermal transfer printing system to ensure high quality printing on fabrics. The thermal transfer system ensures that heat and pressure are evenly distributed across the surface of the fabric, resulting in high-resolution, vibrant and durable prints.

Product Parameters

| model | ba42120 |

| diameter | 4200mm |

| width | 1200mm |

| voltage | 220v 380v |

| power | 28kw |

| temperture | 0-400℃ |

| speed/hr | 80-120m/h |

| packing Size | 3.68*2.6/1.3m |

| weight | 1200kg |

| warranty | 1yeay |

Product Details

Equipment advantage

01.US" DuPont" raw materials blanket

02.Sigle Drum

03.Imported heating pipe

04. Automatic alarm device

05.Air shaft winding

06.Copper carbon brush collectting ring

The advantages of Roll To Roll Heat Press Machine mainly include efficient production capacity and consistent heating effect. Through the continuous roller design, this machine can process a large amount of materials in a short time, greatly improving production efficiency. In addition, the machine's precise temperature and pressure control ensures that each section of material receives uniform heat treatment, thus ensuring product quality and consistency. These characteristics give it significant advantages in mass production.

In conclusion, this heat press sublimation roller automatic wind-up printing machine with air-filled shaft technology is a must-have tool for producing high-quality printing in the textile industry. Reliable, efficient and economical, this machine is ideal for businesses looking to increase production capacity while maintaining print quality.

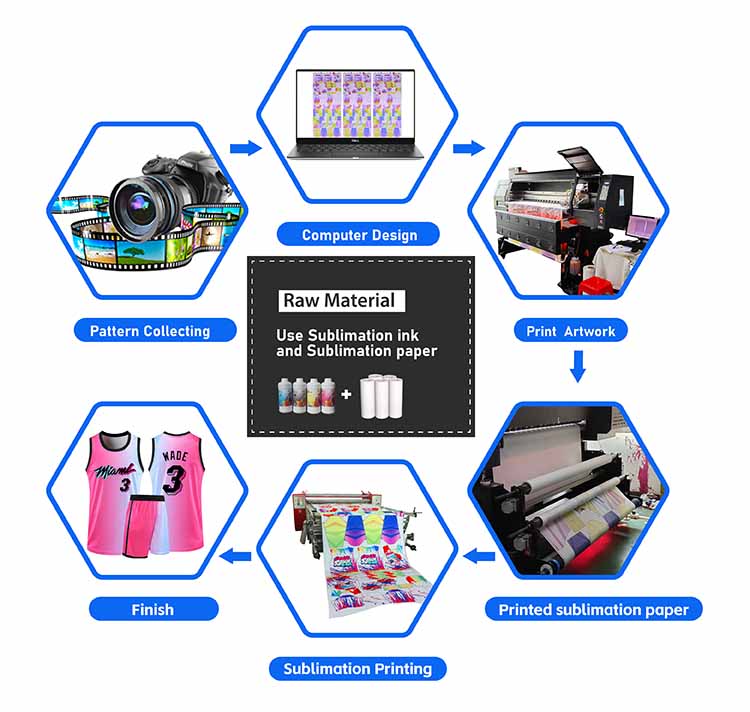

Printing Process

In terms of application fields, Roll To Roll Heat Press Machine is widely used in industries such as textile printing and dyeing, film materials, electronic components, and solar panels. In the textile industry, it can be used for thermal transfer printing of T-shirts, flags, advertising banners, etc.; in the electronics industry, it is used in the manufacturing of flexible circuit boards. In addition, this machine is used in the development and production of new materials, such as high-performance composites and thin-film solar cells, demonstrating its importance and broad applicability in a variety of industrial applications.

Samples

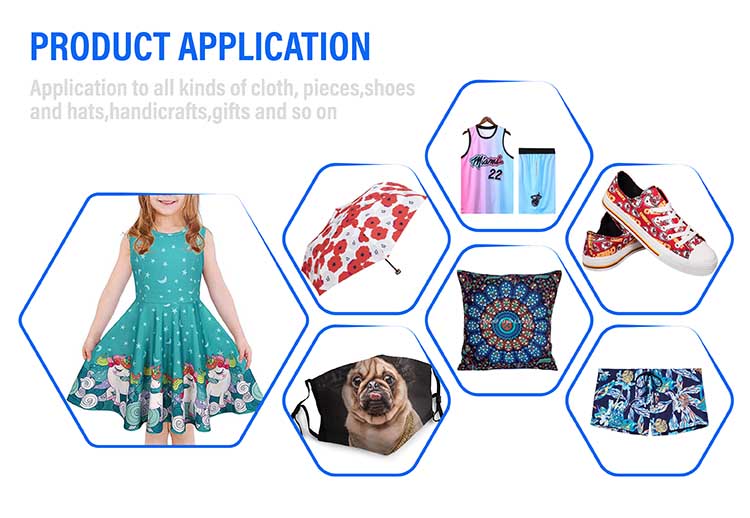

Applicable to all kinds of cloth,pieces ,shoes and hats,handicrafts ,gifts and so on.

FAQ

How to ensure uniform heating of Roll To Roll Heat Press Machine?

Methods to ensure uniform heating include regular calibration of the temperature control system, checking the status of the heating elements, and ensuring that the tension of the material is evenly distributed between the rollers.

Why is there sometimes noise when the machine starts?

Noise can be caused by several factors, including worn roller bearings, loose belts, or worn gears in the drive system. Regular maintenance and lubrication can reduce noise.

How to deal with wrinkles in the heat transfer process?

Wrinkles are usually caused by uneven material tension or uneven roller surface. Ensuring proper material tension and regular cleaning and maintenance of the roller surface can effectively reduce wrinkles.

Why do finished products sometimes have uneven colors?

Uneven colors can be caused by unstable temperature or uneven pressure distribution. Regularly calibrating the machine's temperature and pressure control systems and ensuring that the material is properly positioned between the rollers can improve color consistency.

How to avoid material slipping between the rollers?

Slipping problems are usually related to insufficient material tension or insufficient surface friction. Adjusting the tension control system, ensuring that the material has proper tension before entering the roller, and selecting the appropriate material surface treatment can effectively avoid slipping.

How to avoid frequent activation of the overheating protection device during machine operation?

Frequent activation of the overheating protection device may be caused by a temperature sensor failure or an abnormal heating system. Regularly check the status of the temperature sensor and the operation of the heating system to ensure that the temperature control system is working properly.

How to maintain the drum surface of the machine?

The drum surface needs to be cleaned regularly to avoid stains and residue accumulation. In addition, regularly check whether there are scratches or wear on the drum surface, and repair or replace it in time to extend the service life of the drum.

How to improve the work efficiency of the machine?

Ways to improve work efficiency include optimizing production processes, arranging work tasks reasonably, and ensuring that the machine continues to run for the longest time. Regular maintenance and maintenance of the machine to reduce downtime are also important means to improve efficiency.

What should be paid attention to when the machine is running in a high temperature environment?

When running in a high temperature environment, pay attention to maintaining good ventilation to avoid overheating of the machine. Check the cooling system regularly to ensure its normal operation. Appropriately lowering the working temperature and avoiding long-term high-temperature operation can also extend the service life of the machine.