Roll to Roll Sublimation Printing Machines are specialized equipment used in the textile and apparel industry for creating customized clothing, fashion designs, home decor items such as curtains and upholstery fabrics, sports and team apparel, soft signage like banners and flags, and custom fabric printing for bedding, tablecloths, and linens.

They are also utilized in producing advertising and promotional items, interior design elements like wallpapers and murals, and high-quality art reproductions. These machines offer benefits such as high-resolution and detailed prints with vibrant colors, durability with prints resistant to fading, versatility for various materials, and eco-friendliness due to minimal waste and water-based inks, making them essential for industries requiring high-quality, durable, and customizable printed fabrics.

Product Description

The role of a 420mm Roll To Roll Heat Press Machine is to transfer materials from one location to another using a series of rollers. The machine is designed to handle a variety of materials, including paper, film, textiles, and other materials, and can move them quickly and efficiently.

Product Parameters

| model | ba42120 |

| diameter | 4200mm |

| width | 1200mm |

| voltage | 220v 380v |

| power | 28kw |

| temperture | 0-400℃ |

| speed/hr | 80-120m/h |

| packing Size | 3.68*2.6/1.3m |

| weight | 1200kg |

| warranty | 1yeay |

Product Details

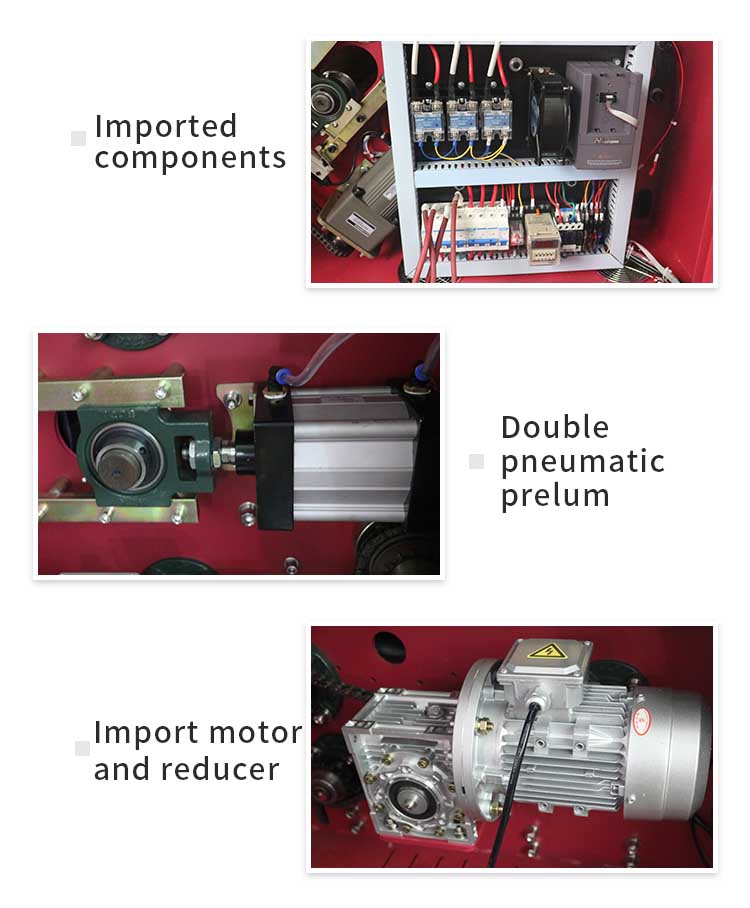

Equipment advantage

01.US" DuPont" raw materials blanket

"DuPont" raw materials blanket with the thickness of 10mm. Roll To Roll Heat Press Machine is imported from the United States, which not only has good transfer effects but also long service life.

02.Sigle Drum

Seamless steel tube roller, inside and outside circle grinding, surface plating Teflon, constantly heating, no color difference.

03.Imported heating pipe

The main wallboard (electric box) is made of 10mm thick steel plate by the application of Italian CNC wire,cutting technology, with high precision.

04. Automatic alarm device

Automatic alarm device can display the current temperature. If the temperature overpasses the set temperature ,it will output signal promptly by triggering the alarm.

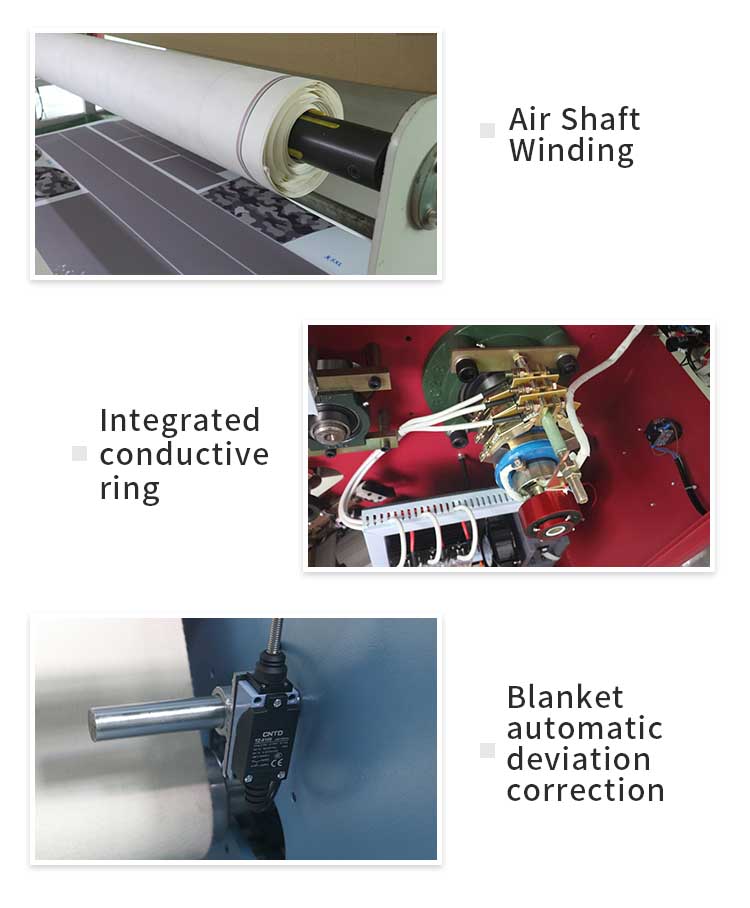

05.Air shaft winding

Air shaft collect the transfer paper and protective paper,helps delivery and rool up more paper tightly instead of lobor force.

06.Copper carbon brush collectting ring

Carbon brush connects collector ring by the electric conduction directly, which not only has good conductive performance but low maintenance costs, enjoying a long service life.

Printing Process

Samples

Applicable to all kinds of cloth,pieces ,shoes and hats,handicrafts ,gifts and so on.

FAQ

What types of materials are Roll to Roll Sublimation Printing Machine suitable for?

This machine is mainly suitable for polyester and its blended fabrics, but can also be used on other materials where thermal transfer is feasible, such as certain plastics and coated metals.

How to ensure the color vividness and details of printed patterns?

Using high-quality ink and paper, as well as the correct temperature and pressure settings, ensures vibrant colors and detail in your printed patterns.

How fast can this machine print?

Printing speed depends on the specific machine model and print settings, and can usually reach tens to hundreds of square meters per hour.

How to avoid fading and fading problems during printing?

Use high-quality dyes and appropriate fixation time to ensure that the dyes are completely sublimated and embedded in the material fibers at high temperatures, which can effectively avoid fading and discoloration problems.

Is the machine complicated to operate? Need professional training?

The operation is relatively simple, but to ensure the best results, it is recommended that operators receive basic professional training and machine maintenance knowledge.

How to clean and maintain Roll to Roll Sublimation Printing Machine?

Regularly clean the print head and roller, use recommended cleaning agents, and regularly inspect and replace worn parts to ensure long-term stable operation of the machine.

Is this machine environmentally friendly?

Yes, the sublimation printing process uses water-based inks, produces less waste, and does not require the use of chemical solvents, making it relatively environmentally friendly.

How big a pattern can be printed?

The size of the printed pattern depends on the width of the machine, and patterns with a width between 1.6 meters and 3.2 meters can usually be printed.

Does the machine have special requirements for power and environment?

Yes, a stable power supply and proper ventilation environment are required to ensure the normal operation and heat dissipation of the machine.

How cost-effective is using a Roll to Roll Sublimation Printing Machine?

The initial investment is relatively large, but due to its efficient production speed and low scrap rate, it is very cost-effective in the long run, especially suitable for mass production.