Garment Roller Sublimation Heat Transfer Machine is a machine specially designed for garment printing, which transfers special dyes to the garment fabrics by hot pressing technique to achieve patterns and designs.

Product Description

420mm Roll To Roll Heat Transfer Printing Machine is an efficient, high-quality, easy-to-operate Printing Machine with a wide range of printing applications, providing users with an excellent printing experience.

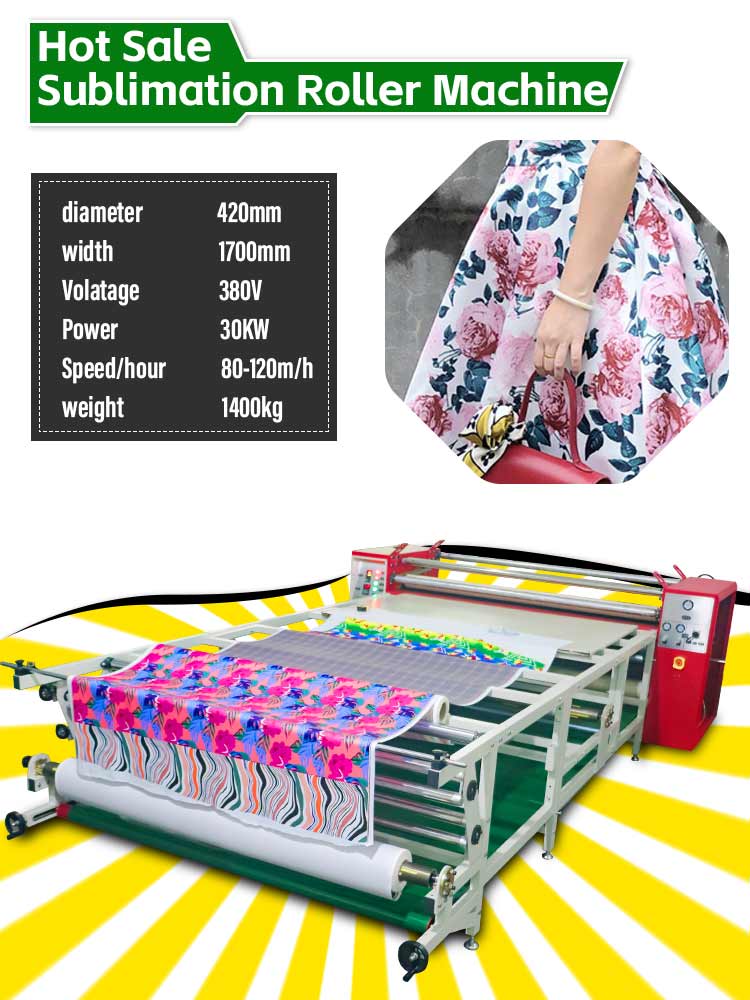

Product Parameters

| Model | ba42170 |

| Diameter | 4200mm |

| Width | 1700mm |

| Coltage | 220v 380v |

| Power | 28kw |

| Temperture | 0-400℃ |

| Speed/hr | 80-120m/h |

| Packing size | 3.68*2.6*1.3m |

| Weight | 1400kg |

| Warranty | 1yeay |

Product Details

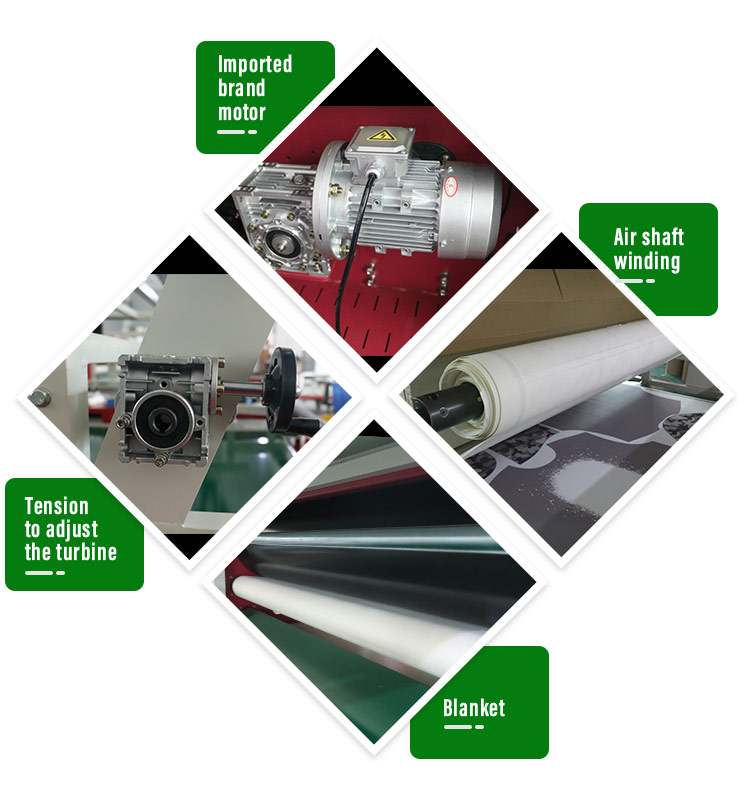

Equipment advantage

1. High-efficiency production: 420mm width and high-speed transmission system enable this machine to complete fast printing of a large number of textiles with high efficiency.

2. High quality: It uses a high-quality print head and control system to ensure the clarity and color depth of the printed image.

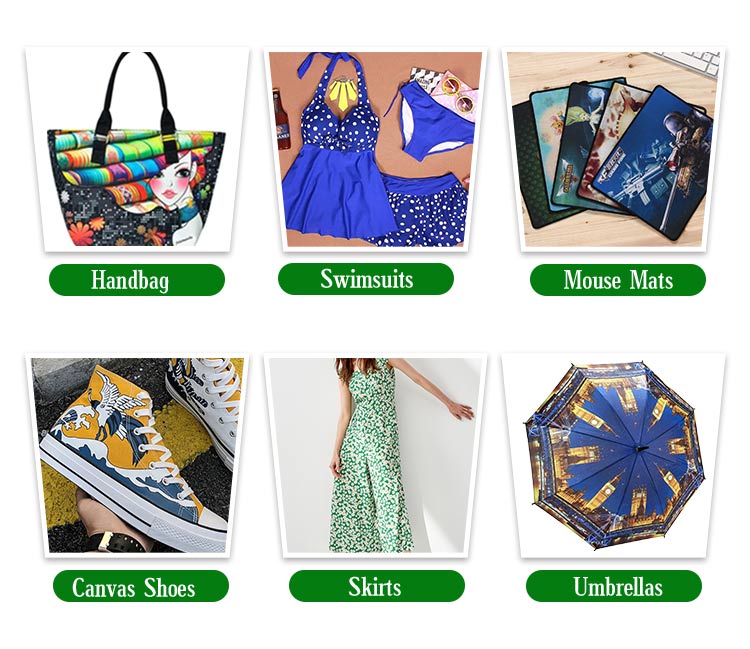

3. Multifunctional: In addition to textile printing, this machine can also be used for printing logos, stickers, car logos, etc.

Overall, a Roll To Roll Heat Transfer Printing Machine is a useful tool for many manufacturing and production processes, providing a reliable and efficient way to transfer materials and products from one stage of the process to another.

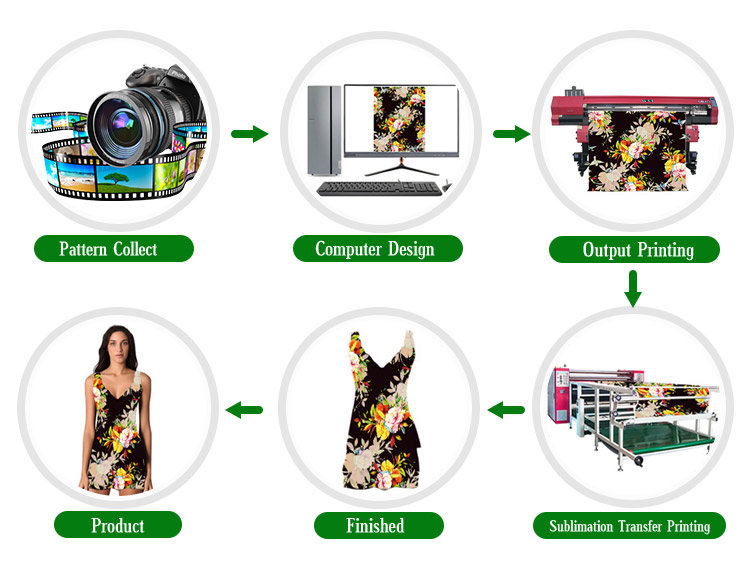

Printing Process

Samples

The 420mm dimension refers to the width of the rollers and may vary according to specific applications and requirements. This machine can be used for a variety of materials, including various fabrics, pieces, shoes and hats, handicrafts, gifts, etc. If you are interested in our products, please contact us.

Working Principle:

Dyes are first printed on special transfer paper.

The garment fabric is placed between the transfer paper and the heated roller.

When the machine is started, the heated roller heats the fabric and the transfer paper, causing the dye to sublimate (i.e., go directly from a solid to a gas) and penetrate the fabric.

Upon cooling, the dye solidifies on the fabric, creating a long-lasting, vibrant pattern.

Technical features:

Bright colours and clear patterns: as the dyes penetrate directly into the fabric fibres, the colours are long lasting and do not fade easily.

Suitable for a wide range of fabrics: including polyester, nylon, blends, etc.

Enables fast production of large quantities: the drum design allows the machine to work continuously, increasing production efficiency.

Application Areas:

Sportswear: T-shirts, sports trousers, sports socks, etc.

Casual wear: shirts, skirts, hats, etc.

Personalisation: wedding wear, team wear, company uniforms, etc.

Maintenance and upkeep:

Regular cleaning: keep the inside and outside of the machine clean to avoid the effect of dust and dirt on the equipment.

Check the drum: Make sure the drum surface is flat and free from damage or scratches.

Replacement of worn parts: if the heating element, drum and other parts are badly worn, they should be replaced in time.

Environmental protection and energy saving:

Choose dyes and transfer paper that meet environmental protection standards to reduce pollution to the environment.

Energy-saving design: choose equipment with energy-saving functions, such as automatic adjustment of temperature and pressure.

Development trend:

Intelligent: Realise intelligent operation and monitoring of equipment by introducing advanced control system and sensor technology.

Customisation: provide customised solutions and services according to the needs of different customers.

Green: pay more attention to environmental protection and sustainability, develop more environmentally friendly dyestuffs and transfer papers, and reduce environmental pollution in the production process.