Product Description

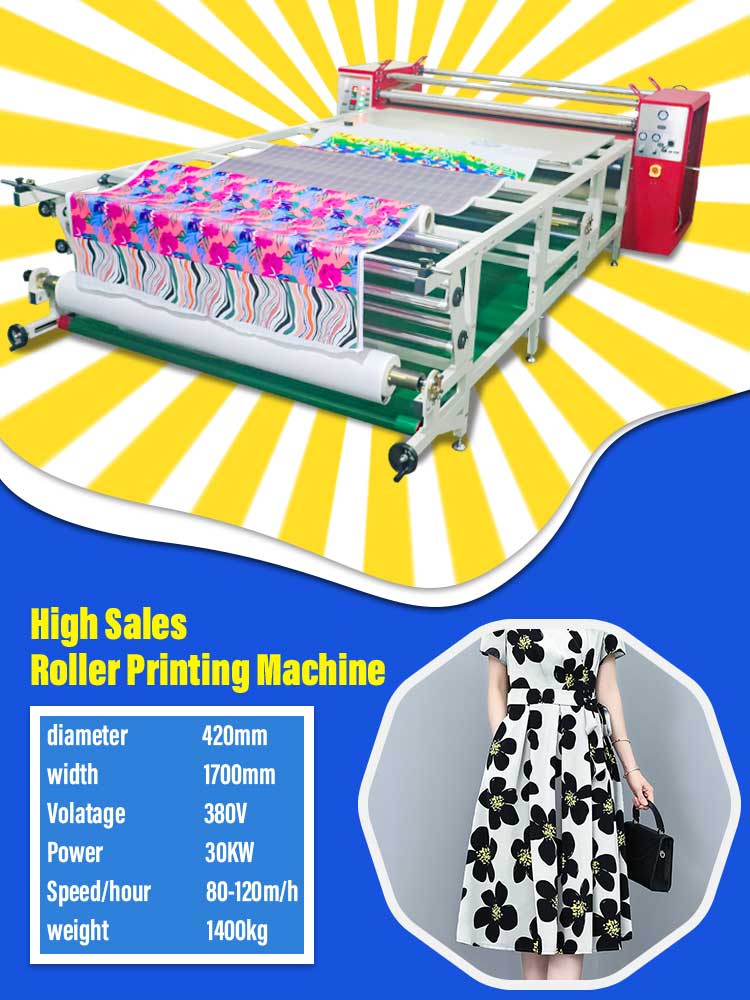

Hot Selling High Output Roller Printing Machine is a versatile and efficient printing machine that can handle a wide range of materials, including paper, film, vinyl, and textiles. With its large diameter rollers and high-precision digital control system, it can produce high-quality prints with excellent color accuracy and consistency.

This printing machine comes with a range of advanced features, including automatic tension control, air-expansion shafts, and a user-friendly interface. Its high output capacity and fast production speeds make it an ideal choice for fast-paced printing environments.

Its roll-to-roll design enables users to effortlessly print long lengths of continuous material without interruption, while its adjustable printing pressure and temperature make it easy to create customized prints on a variety of materials.

Product Parameters

| Model | ba42170 |

| Diameter | 4200mm |

| Width | 1700mm |

| Coltage | 220v 380v |

| Power | 28kw |

| Temperture | 0-400℃ |

| Speed/hr | 80-120m/h |

| Packing size | 3.68*2.6*1.3m |

| Weight | 1400kg |

| Warranty | 1yeay |

Product Details

Equipment advantage

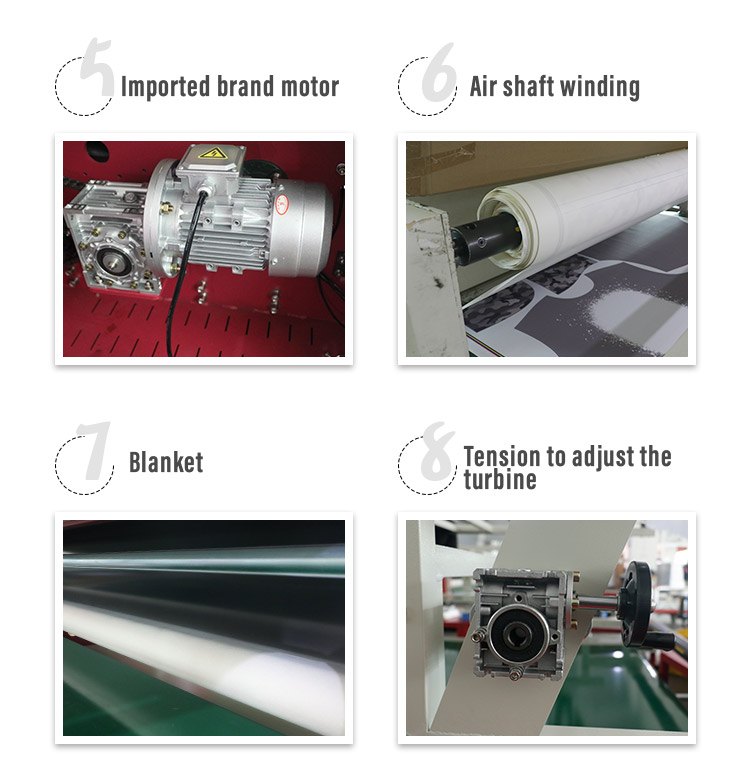

1. High-efficiency production: The large-diameter cylinder and high-precision digital control system configured by the equipment can achieve high-quality printing output.

2. High-quality printing effect: The equipment can effectively control the printing pressure and temperature to ensure the color accuracy and consistency of the printing effect.

3. Multiple adaptability: The equipment is suitable for various materials, including paper, film, vinyl, etc.

4. Advanced functions: Advanced functions such as automatic tension control, pneumatic expansion axis, and user-friendly interface have improved efficiency and made production easier.

5. Quality assurance: The equipment is made of high-quality materials, well-made, long-term stable operation, and high-quality printing effect.

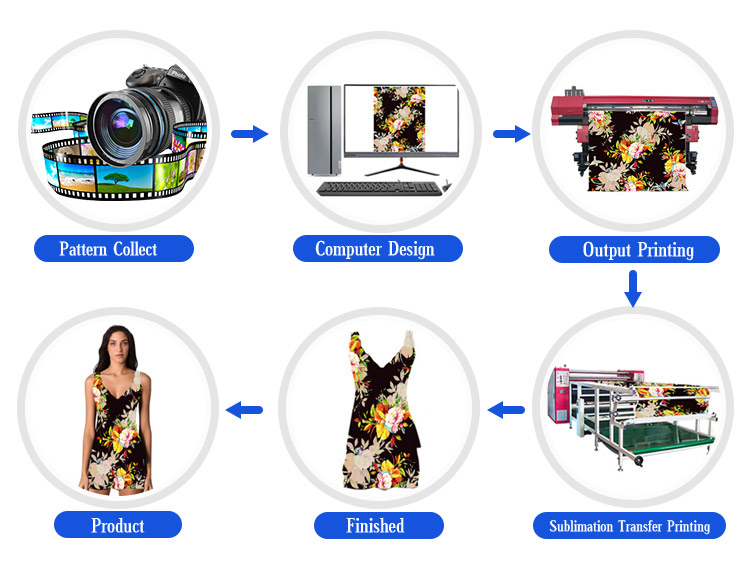

Printing Process

Samples

The usage advantages of a Large Heat Press Machine Roller Printing Machine are manifold, making it a valuable asset across various industries:

Efficiency

Large heat press roller printing machines can handle high volumes of printing quickly and efficiently, making them ideal for mass production scenarios where time is of the essence.

Versatility

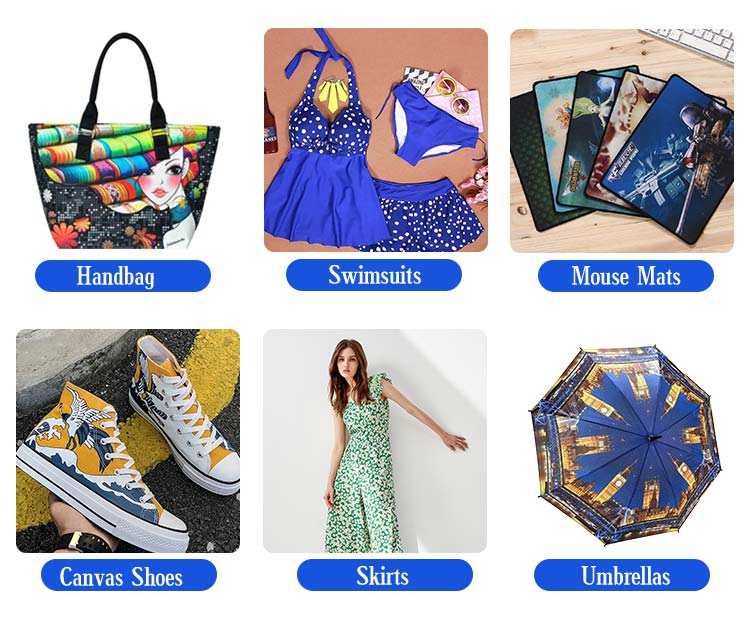

These machines can accommodate a wide range of substrates, including fabrics, paper, plastics, and metals, allowing for diverse printing applications across different industries.

High Quality Results

They enable the transfer of intricate designs, patterns, and graphics with precision and clarity onto substrates, ensuring high-quality finished products with vibrant colors and crisp details.

Reduced Labor Requirements

Large heat press roller printing machines streamline the printing process, requiring minimal manual labor compared to traditional printing methods, thereby increasing productivity and reducing labor costs.

Environmental Friendliness

Compared to traditional printing methods such as screen printing, large heat press roller printing machines produce fewer waste by-products and use less energy, contributing to environmental sustainability.

Durability

These machines are built to withstand heavy-duty usage in industrial and commercial settings, ensuring long-term reliability and durability with minimal downtime.

The 420mm dimension refers to the width of the rollers and may vary according to specific applications and requirements. This machine can be used for a variety of materials, including various fabrics, pieces, shoes and hats, handicrafts, gifts, etc. If you are interested in our products, please contact us.

Application Areas:

Textile industry

Used for textile printing and pattern making, such as T-shirts, shirts, scarves and so on.

Packaging industry

Used for the printing of various packaging materials, such as plastic bags, paper bags, paper boxes and so on.

Advertising industry

For advertising posters, leaflets and other printed materials.

Other industries

Such as leather products, shoes, toys and other areas of printing needs.

Maintenance and upkeep:

Regular Inspection

Regularly inspect and maintain the equipment to ensure the normal operation and prolong the service life of the equipment.

Cleaning and Maintenance

Keep the equipment clean and dry to avoid the influence of dust and dirt on the equipment.

Repair and Replacement

For the faulty equipment parts, they should be repaired or replaced in time to ensure the normal operation of the equipment.

Our service:

Intelligent

With the development of technology, Large Heat Press Machine Roller Printing Machine will become more and more intelligent to achieve more efficient automated production and more accurate quality control.

Environmental protection and energy saving

Future equipment will pay more attention to environmental protection and energy saving, using more environmentally friendly materials and more energy-saving technology to reduce the impact on the environment and reduce energy consumption.

Customisation

According to the needs of different industries and customers, provide customised solutions and personalised services to meet the individual needs of different customers.