Textile Roller Printing Machine employs rollers as a tool for printing, transferring patterns by applying pressure and pigment to the surface of the fabric. This machine usually consists of multiple rollers, each of which is responsible for transferring a colour or part of a pattern to create intricate designs. It can be used to print on various types of textiles, including cotton, silk, polyester, and more.

The Textile Roller Printing Machine works as follows: first, the fabric is tensioned on a platform, then the printed design is transferred to the rollers, which are coated with pigment. As the fabric passes over the rollers, pressure and pigment transfer the design to the fabric, creating the desired print. This method is fast and efficient, allowing large quantities of printed fabric to be produced in a short period of time.

This machine is commonly used in textile factories and dyeing plants for the production of a wide range of textiles such as garments, home textiles, decorative items and more. It is capable of achieving high quality and accurate printing results and is widely used in the textile industry.

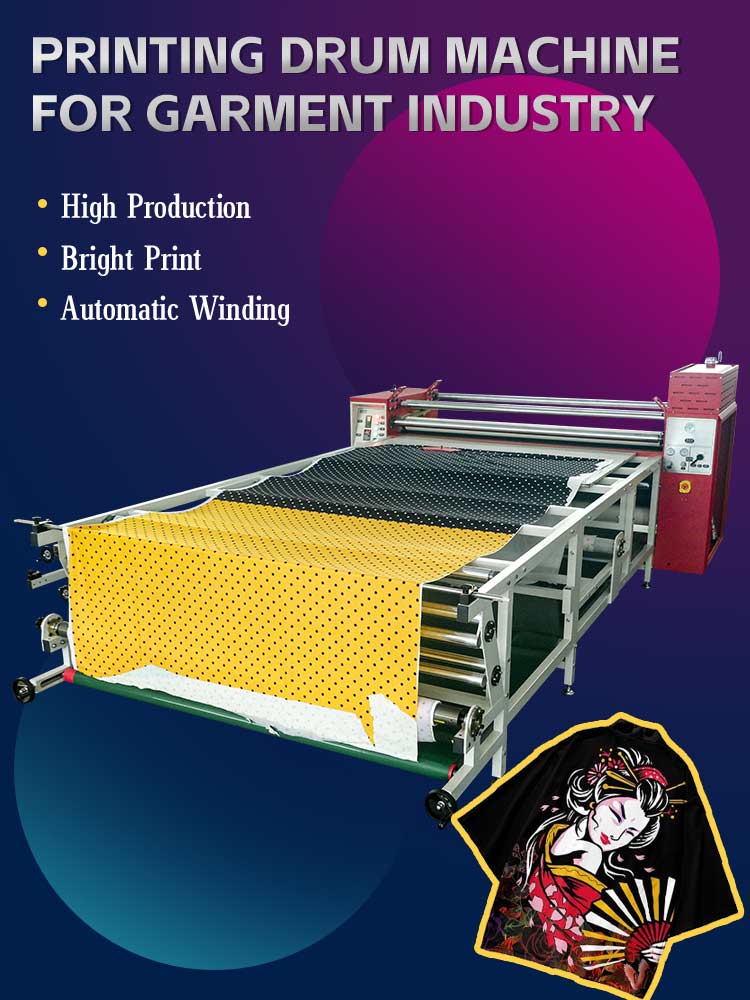

Product Description

A heat press Sublimation Machine is a machine used to print designs onto textiles and other materials.420mm Roll To Roll Heat Transfer Printing Machine is a type of equipment used in manufacturing and production processes. It consists of a series of rollers arranged in a line, with each roller powered by a motor to rotate it. The 420mm Roll To Roll Heat Transfer Printing Machine is used to transfer materials or products from one process or station to another, with the rollers providing a smooth and continuous movement of the items.

Product Parameters

| Model | ba42170 |

| Diameter | 4200mm |

| Width | 1700mm |

| Coltage | 220v 380v |

| Power | 28kw |

| Temperture | 0-400℃ |

| Speed/hr | 80-120m/h |

| Packing size | 3.68*2.6*1.3m |

| Weight | 1400kg |

| Warranty | 1yeay |

Product Details

Equipment advantage

01.US" DuPont" raw materials blanket

02.Sigle Drum

03.Imported heating pipe

04. Automatic alarm device

05.Air shaft winding

06.Copper carbon brush collectting ring

Overall, a Roll To Roll Heat Transfer Printing Machine is a useful tool for many manufacturing and production processes, providing a reliable and efficient way to transfer materials and products from one stage of the process to another.

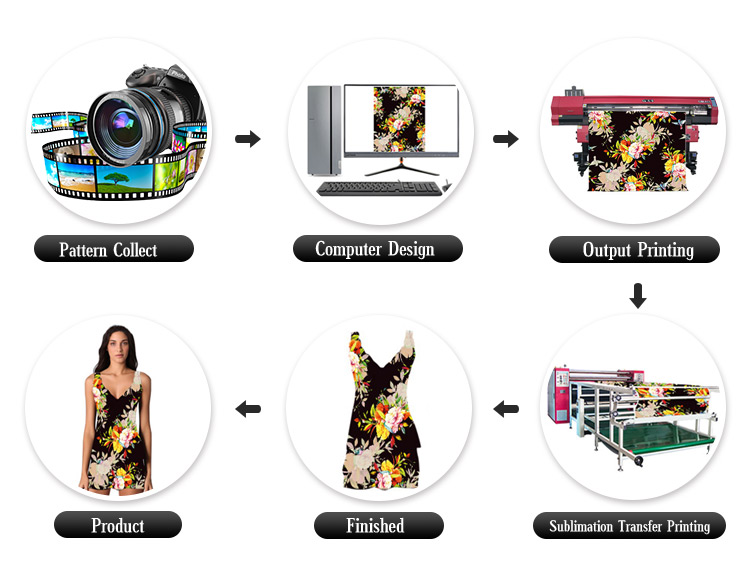

Printing Process

Samples

The 420mm dimension refers to the width of the rollers and may vary according to specific applications and requirements. This machine can be used for a variety of materials, including various fabrics, pieces, shoes and hats, handicrafts, gifts, etc. If you are interested in our products, please contact us.

When using a Heat Press Sublimation Machine, there are several important precautions to consider:

Safety First: Always follow the manufacturer's instructions for safe operation of the machine. Ensure that all safety features are in place and functioning properly.

Heat Settings: Pay close attention to the recommended temperature settings for the specific materials you are working with. Using incorrect temperatures can result in poor quality transfers or damage to the material.

Pressure Adjustment: Proper pressure is essential for achieving crisp and clear transfers. Adjust the pressure according to the thickness of the material being printed on, ensuring even distribution across the entire surface.

Transfer Alignment: Ensure that the transfer paper or sublimation film is properly aligned with the material before pressing. Misalignment can result in blurred or distorted images.

Preparation of Substrates: Pre-treat or pre-press substrates as necessary to remove moisture and wrinkles. This helps ensure better adhesion and transfer of the sublimation ink.

Ventilation: Sublimation involves the release of gases and fumes during the heating process. Work in a well-ventilated area or use appropriate ventilation equipment to prevent inhalation of potentially harmful fumes.

Cooling Time: Allow sufficient time for the transferred design to cool down before handling or removing the material from the machine. Premature handling can smudge the design and affect the final result.

Maintenance: Regularly clean the heating platen and machine surfaces to prevent buildup of ink residues, which can affect transfer quality and machine performance.

Quality Materials: Use high-quality sublimation inks, transfer papers, and substrates for optimal results. Inferior materials may result in faded prints or poor adhesion.

Practice and Experimentation: Familiarize yourself with the machine by practicing on scrap materials before working on final products. Experiment with different settings and techniques to achieve the desired results.

By following these precautions, you can ensure safe and successful operation of a Heat Press Sublimation Machine, achieving high-quality sublimation prints consistently.