Sublimation Roll Heat Press Machine is a device specially used to transfer the pattern printed by sublimation ink to materials such as cloth, paper, and ceramics. Sublimation Roll Heat Press Machine can directly sublimate the sublimation ink into gas through high temperature and high pressure, and then penetrate into the material to form a permanent pattern with bright colors, rich details, and not easy to fade and fall off.

Features

High-resolution printing capability: The Sublimation Roll Heat Press Machine has a resolution of up to 1440 x 1440 dpi, which can achieve fine and clear image details. It is suitable for products that require high-precision printing, such as customized clothing, sports equipment, and home decorations.

Fast printing speed: The Sublimation Roll Heat Press Machine can provide a printing speed of more than 50 meters per minute, which significantly improves production efficiency and is suitable for large-scale production, especially in batch customization orders with high timeliness requirements, which can reduce delivery cycles.

Versatile printing options: Supports thermal transfers of different widths, including a maximum width of 1.6 meters, which can adapt to various types of fabrics (such as polyester, nylon, etc.) and other transfer materials (such as metal, ceramic, etc.), making it widely used in many fields such as clothing, advertising, and household goods.

User-friendly operation interface: Equipped with a touch screen operation interface with real-time data display function, the operation interface is intuitive and easy to understand, reducing the operator's learning time.

Durable structure and long-term performance: The structure is made of sturdy aluminum alloy and stainless steel materials, which are resistant to high temperatures and corrosion, and can maintain stable operation in high-temperature and high-pressure working environments, with a service life of more than 10 years.

Consistent and reliable output: The Sublimation Roll Heat Press Machine is equipped with a high-precision temperature control system to ensure that the temperature control accuracy is within ±2℃, ensuring that the color of the pattern is consistent and the quality is stable each time it is transferred, meeting high-standard production requirements.

Low maintenance requirements: The design focuses on reducing wear and maintenance requirements. The equipment only needs regular cleaning and lubrication, reducing downtime.

Energy-saving design: With intelligent energy-saving technology and high-efficiency heat source, the equipment energy efficiency ratio reaches 95%, reducing energy consumption and operating costs. Compared with traditional equipment, it can reduce electricity consumption by more than 30%, meeting the requirements of green and environmentally friendly production.

Advanced technology improves precision and accuracy: The equipment integrates advanced PID temperature control system and pressure automatic adjustment technology to ensure precise control of factors such as temperature, pressure and time, with an accuracy of ±1 second, meeting the needs of thermal transfer of different materials.

Customizable settings: The machine allows users to adjust parameters such as heat pressing time, temperature, pressure, etc. according to different production needs. Up to 50 sets of preset processes can be stored to quickly switch between different production modes, greatly improving production flexibility.

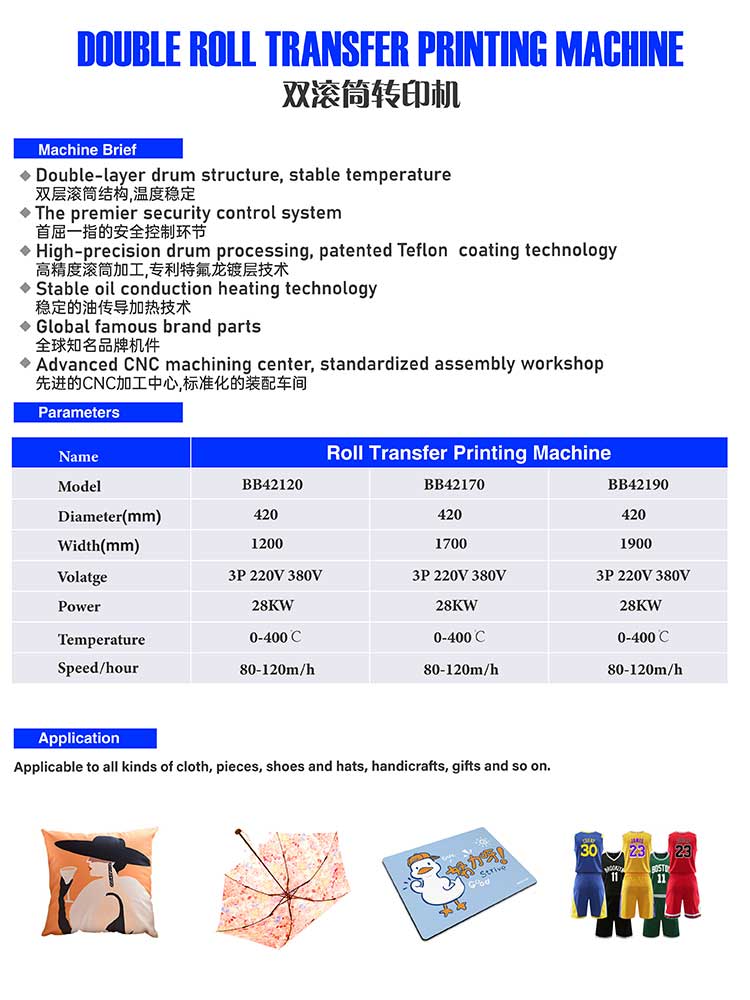

Parameter

| Name | Sublimation Roll Heat Press Machine |

| Model | BB42120 |

| Diameter | 420MM |

| Width | 1200MM |

| Voltage | 110v / 220v / 380V |

| Power | 25kw |

| Temperature | 0-400°C |

| Speed/hr | 80-120m/h |

| Packing size | 3.68*2.6*1.3m |

| N.W | 1400kg |

Function

Heat-press transfer: transfer the pattern printed by sublimation ink to various materials, such as T-shirts, cloth, paper, ceramics, etc.

Temperature control: The equipment has a precise temperature control system, which can adjust the appropriate temperature according to different material and pattern requirements.

Pressure control: The equipment has a pressure control system, which can adjust the appropriate pressure as needed to ensure the integrity and clarity of the pattern.

Speed adjustment: Some equipment has a speed adjustment function, which can adjust the appropriate speed according to production needs to improve production efficiency.

Application areas

Textile printing: Sublimation drum heat press is one of the important equipment for textile printing, which can be used for printing T-shirts, skirts, pants and other clothes.

Home decoration: It can be used for printing curtains, pillows, tablecloths and other home decorations, adding color and personality to the home environment.

Advertising: It can be used to make advertising banners, posters and other promotional materials, with bright colors and not easy to fade.

Gift customization: It can be used to customize various gifts, such as cups, plates, mouse pads, etc., to add uniqueness and commemorative significance to the gifts.

Maintenance and care

Cleaning equipment: Clean the surface and inside of the equipment regularly, remove residual ink, dust and other debris, and keep the equipment clean and hygienic.

Check temperature and pressure: Check the temperature and pressure control system of the equipment regularly to ensure its normal operation and avoid affecting the printing effect due to unstable temperature or pressure.

Lubricate parts: Regularly add lubricating oil to the moving parts of the equipment to reduce wear and friction and extend the service life of the equipment.

Check power supply and wires: Check the power supply and wires of the equipment regularly to ensure that they are well connected to avoid equipment failure due to power supply or wire problems.

Precautions

Safe operation: When operating the equipment, you should follow the safety operating procedures and avoid direct contact with high-temperature components and high-voltage circuits to avoid burns or electric shock accidents.

Choose the right material: When performing heat transfer, you should choose the right material and ink to ensure the best printing effect.

Adjust the right parameters: According to the requirements of the material and pattern, adjust the appropriate temperature, pressure and speed parameters to obtain the best printing effect.

Avoid long-term continuous work: Although the equipment can work continuously, in order to avoid overheating and wear, long-term continuous work should be avoided as much as possible, and the equipment should be properly rested and cooled.

Regular inspection and maintenance: Regularly inspect and maintain the equipment, discover and solve problems in time, and ensure the normal operation of the equipment and printing effect.

Common problems and solutions

Poor printing effect: The possible reason is insufficient temperature or pressure, or unsuitable material. The solution is to adjust the temperature, pressure and choose the right material.

Equipment failure: The possible reason is power supply or wire problem, or damage to internal parts of the equipment. The solution is to check the power supply and wire connection, or contact after-sales service for repair.

Ink residue: The possible reason is incomplete cleaning or poor ink quality. The solution is to strengthen cleaning work or replace the ink with good quality.

Catalogue

Details

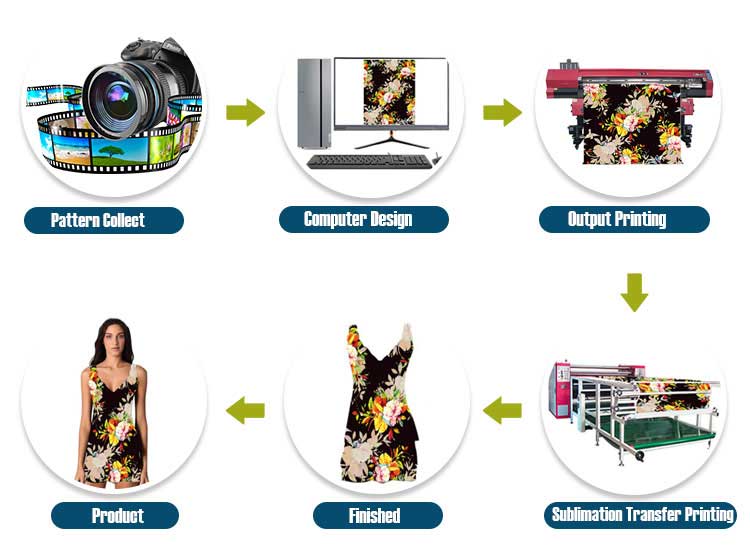

Process

Samples