High-end Clothing Roller Printing Machine

Product Description

A Double Roller Heat Transfer Machine high-end clothing roller printing machine is a specialized printing machine designed for printing patterns or designs onto rolls of fabric that will later be used to create clothing. Here are some features of a high-end clothing roller printing machine:

1.High printing speed: These machines are designed to print at high speeds, allowing for increased production and efficiency.

2.Multiple color printing: High-end clothing roller printing machines can print multiple colors simultaneously, allowing for more intricate and detailed designs.

3.Large printing area: The machines have a large printing area, which allows for printing on wider rolls of fabric.

4.Precise registration: These machines have precise registration capabilities, ensuring that each color layer of the design is perfectly aligned with the others.

5.Automated operation: Many high-end clothing roller printing machines have automated features such as automatic fabric feed and print head movement, which increase efficiency and reduce the need for manual labor.

6.Customizable settings: The machines often have customizable settings for temperature, pressure, and ink flow, allowing for precise adjustments to achieve the desired print quality.

Overall, a 420mm Roller Transfer Machine is a specialized piece of equipment that is designed to print intricate and detailed designs onto rolls of fabric that will be used to create clothing. With high printing speeds, multiple color printing, large printing areas, precise registration, automated operation, and customizable settings, these machines are essential for high-volume clothing manufacturing businesses that require high-quality prints and efficient production.

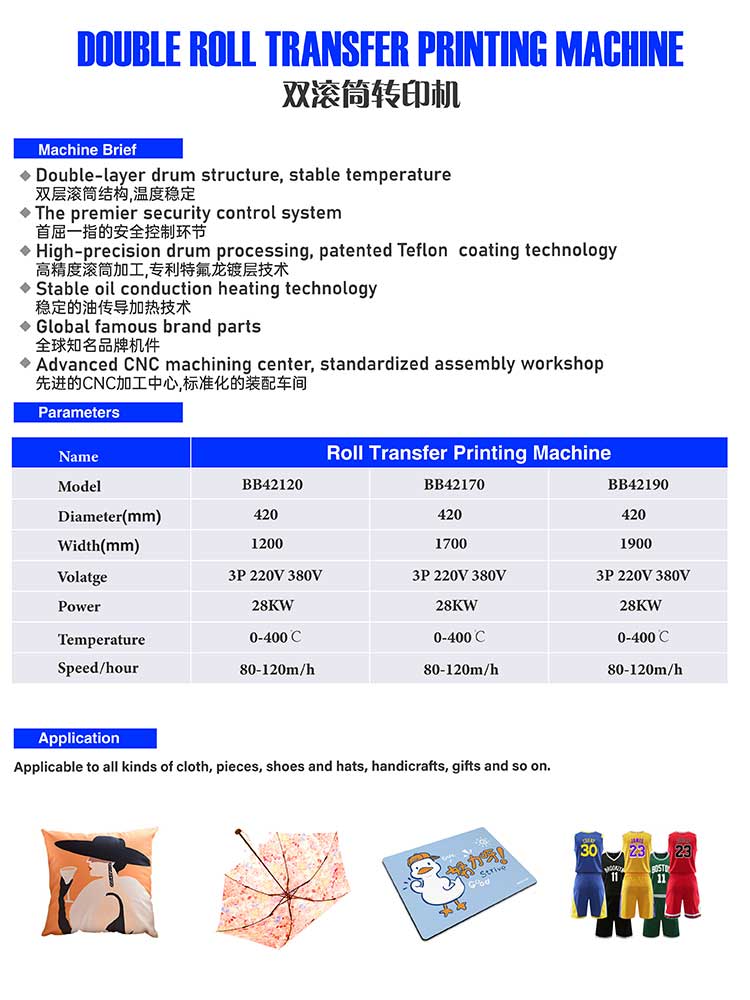

Parameter

| Name | Heat transfer sublimation machine |

| Model | BB42170 |

| Diameter | 420MM |

| Width | 1700mm |

| Voltage | 110v / 220v / 380V |

| Power | 30kw |

| Temperature | 0-400°C |

| Speed/hr | 80-120m/h |

| Packing size | 2.25*0.4*1.5 |

| N.W | 1400kg |

Machine Advantage

Independent welding table, easy to install and remove;

Air up the shaft roller, precise tension control, to ensure that the delivery of paper neat;

Anti-pinch device to ensure safe operation;

Microcomputer operation panel, simple and reliable;

High burning point conveyor blankets, flame retardant performance; blanket thickness uniformity, the transfer effect is good;

Teflon coating heating roller, effectively prevent electrostatic interference in the transfer process, roller temperature is small;

Roller with internal and external precision turning and grinding, uniform thickness, heat transfer stability;

Brand thermal oil, heat stable and uniform;

Adjustable blanket roller rack pressure mechanism, pressure adjustment is simple and convenient;

Independent pneumatic booster agencies to ensure high - pressure environment transfer, to achieve the transfer of color thousands;

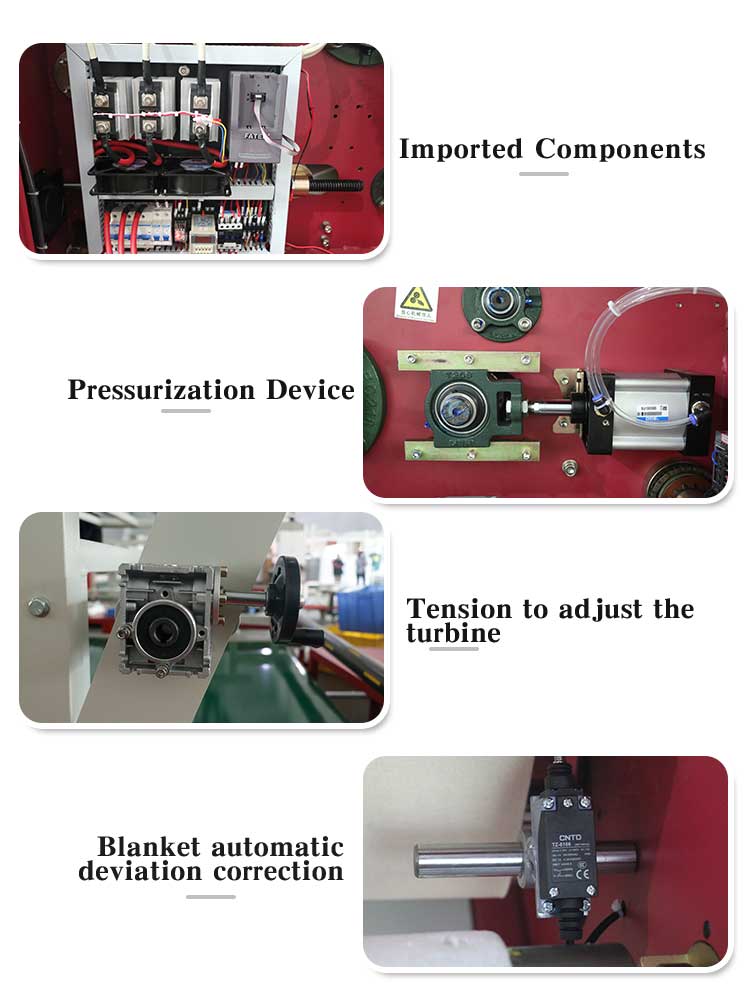

Brand electrical components, long life, low failure rate;

latest collector ring signal transmission, high stability and long life;

PVC conveyor belt, isolation paper reel, ribbon drive shaft speed can be independent and flexible adjustment;

Independent blanket correction structure;

Precise temperature control system, the temperature difference in the range of 5 degrees;

Tension adjustment structure, to ensure that the cloth and paper transfer process of tension balance

Catalogue

Machine Details

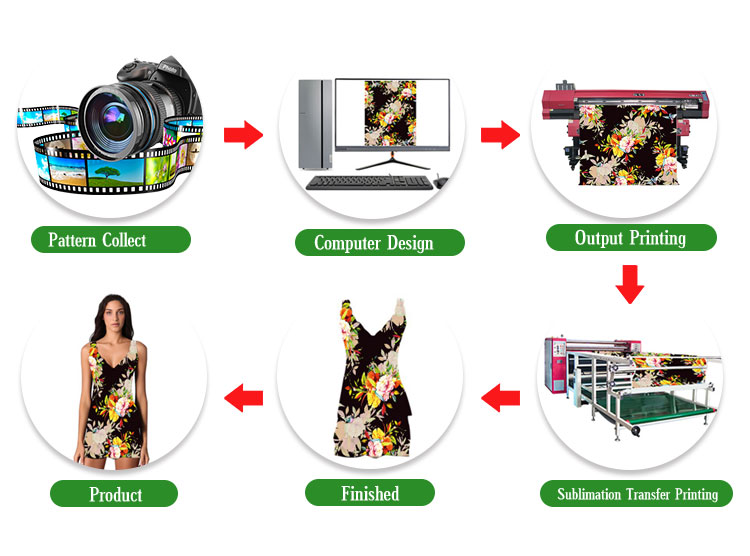

Printing Process

Samples