A High Quality Sublimation Machine Printing Machine is a type of printing equipment used in the sublimation printing process. Sublimation printing is a process in which a design or image is printed onto a transfer paper using special sublimation ink. The transfer paper is then placed onto the substrate, typically a polyester-based fabric, and heat is applied to transfer the ink onto the fabric.

A Double Roller Heat Transfer Machine High Quality sublimation machine Printing Machine is designed to provide high-quality, long-lasting prints with vibrant colors and sharp details. It typically consists of a printer, heat press, and software to design and print the images onto the transfer paper. The heat press applies heat and pressure to the transfer paper and substrate, causing the ink to transfer onto the substrate.

420mm Roller Transfer Machine come in various sizes, ranging from small desktop models suitable for home-based businesses or hobbyists to large industrial models suitable for high-volume production. They can be used to print a wide variety of products, including apparel, home decor items, and promotional items.

The advantages of using a High Quality Sublimation Machine Printing Machine include its ability to produce high-quality, durable prints that will not fade or peel over time. It can also produce a wide range of colors and designs, including photographic images and complex patterns. Additionally, sublimation printing can be done on demand, making it a cost-effective option for small businesses or individuals.

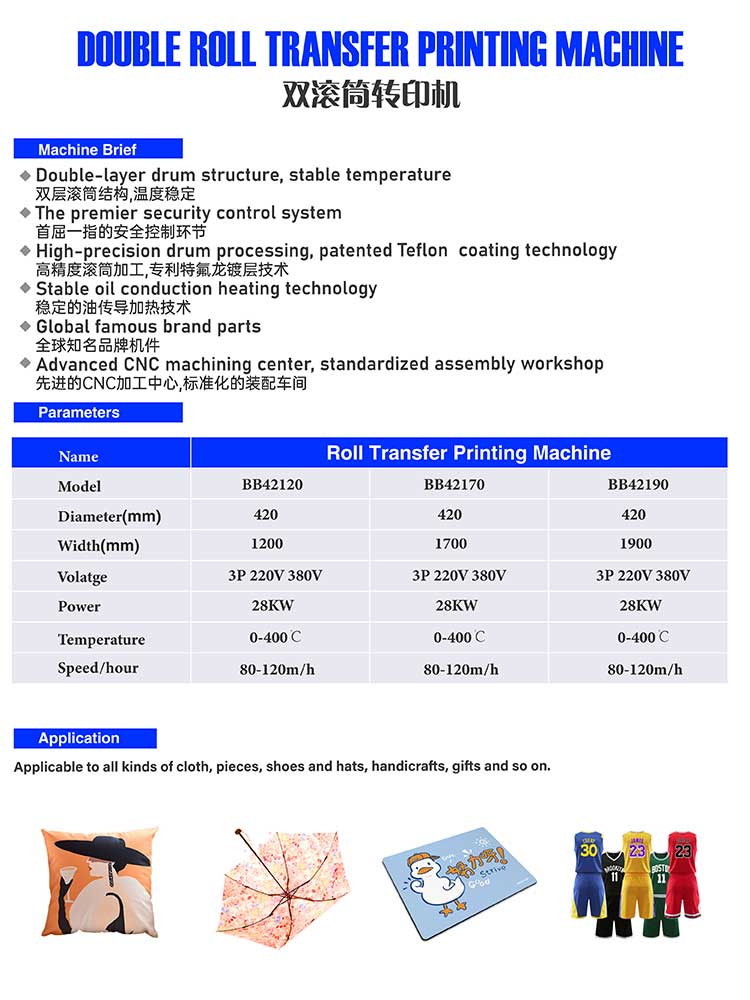

Parameter

Name | Heat transfer sublimation machine |

Model | BB42170 |

Diameter | 420MM |

Width | 1700mm |

Voltage | 110v / 220v / 380V |

Power | 30kw |

Temperature | 0-400°C |

Speed/hr | 80-120m/h |

Packing size | 2.25*0.4*1.5 |

N.W | 1400kg |

Machine Advantage

Independent welding table, easy to install and remove;

Air up the shaft roller, precise tension control, to ensure that the delivery of paper neat;

Anti-pinch device to ensure safe operation;

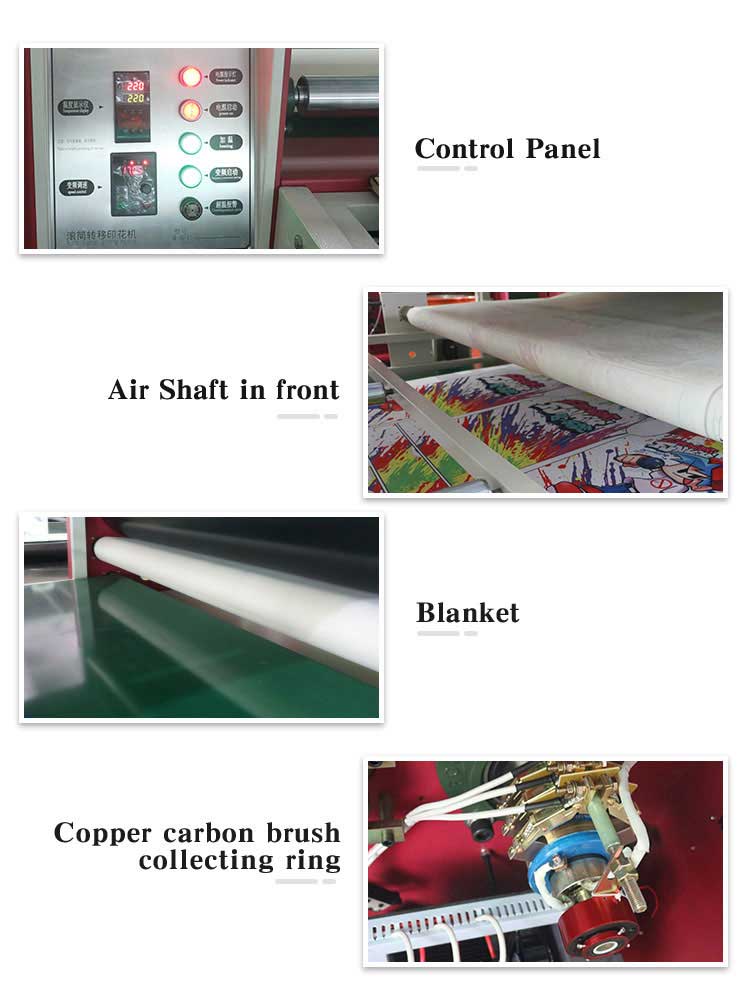

Microcomputer operation panel, simple and reliable;

High burning point conveyor blankets, flame retardant performance; blanket thickness uniformity, the transfer effect is good;

Teflon coating heating roller, effectively prevent electrostatic interference in the transfer process, roller temperature is small;

Roller with internal and external precision turning and grinding, uniform thickness, heat transfer stability;

Brand thermal oil, heat stable and uniform;

Adjustable blanket roller rack pressure mechanism, pressure adjustment is simple and convenient;

Independent pneumatic booster agencies to ensure high - pressure environment transfer, to achieve the transfer of color thousands;

Brand electrical components, long life, low failure rate;

latest collector ring signal transmission, high stability and long life;

PVC conveyor belt, isolation paper reel, ribbon drive shaft speed can be independent and flexible adjustment;

Independent blanket correction structure;

Precise temperature control system, the temperature difference in the range of 5 degrees;

Tension adjustment structure, to ensure that the cloth and paper transfer process of tension balance

Catalogue

Machine Details

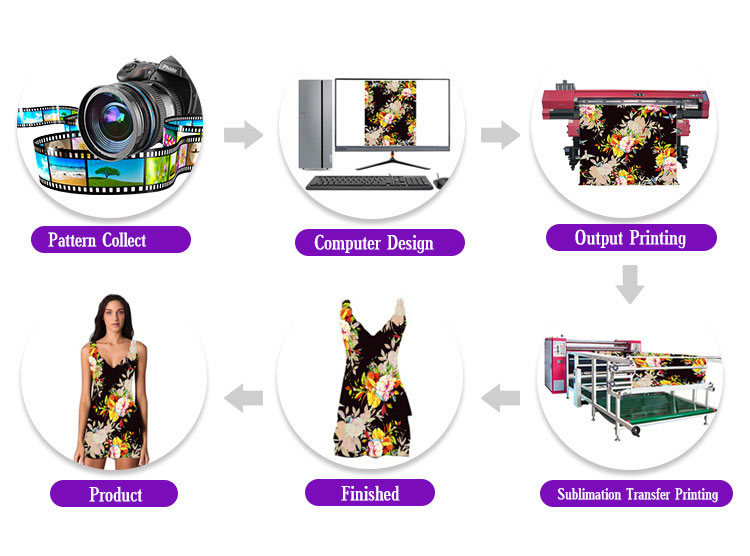

Printing Process

Samples