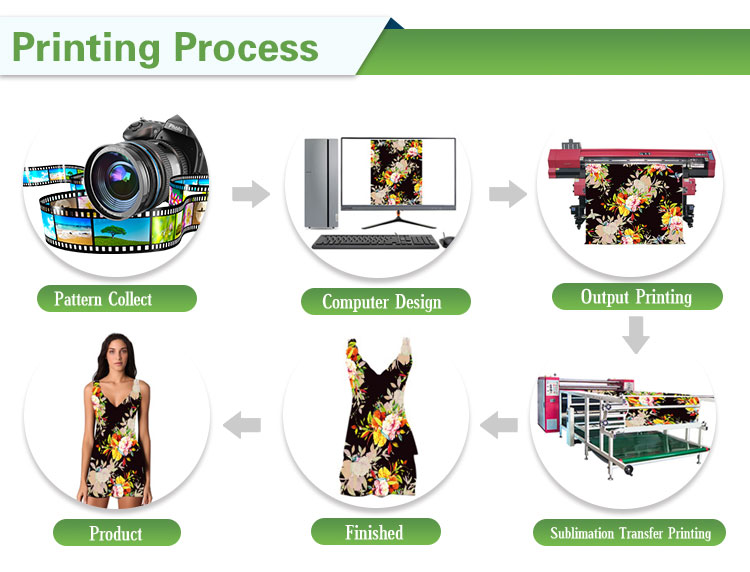

Roll To roll heat transfer machine is a device that transfers pre-printed patterns to substrates by heating. It uses roll materials as input and output, and can realize continuous, efficient, and large-scale thermal transfer operations.

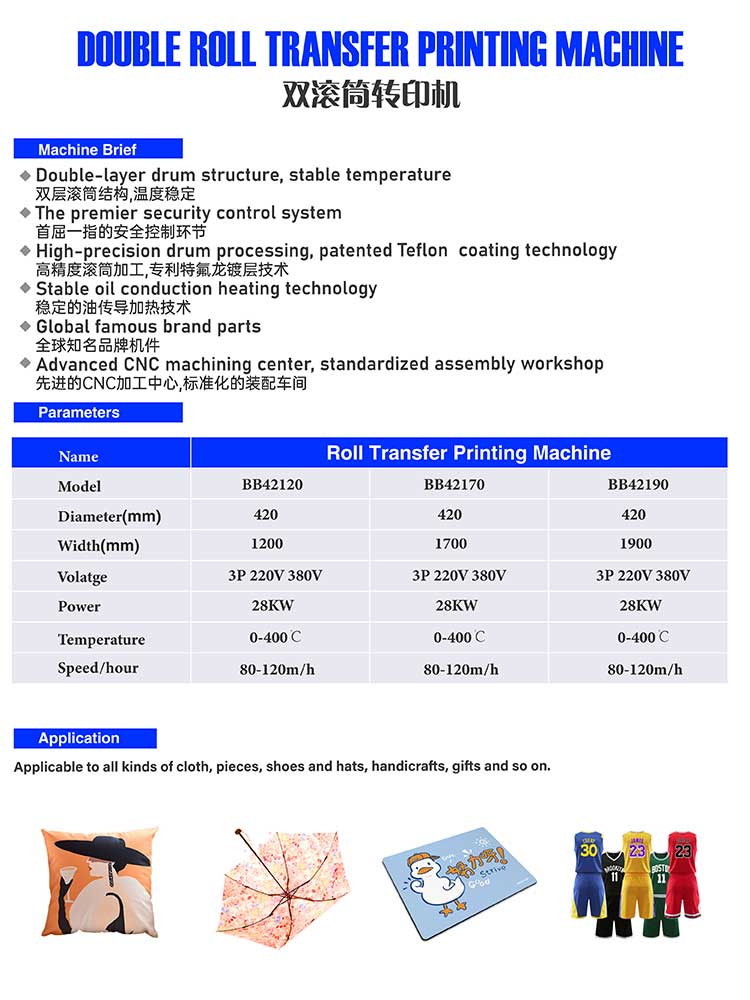

Parameter

| Name | Heat transfer sublimation machine |

| Model | BB42170 |

| Diameter | 420MM |

| Width | 1700mm |

| Voltage | 110v / 220v / 380V |

| Power | 30kw |

| Temperature | 0-400°C |

| Speed/hr | 80-120m/h |

| Packing size | 2.25*0.4*1.5 |

| N.W | 1400kg |

Features

High efficiency: The roll-to-Roll Heat Transfer Machine adopts a continuous working mode, which can quickly complete the thermal transfer of a large number of materials and significantly improve production efficiency.

High precision: The equipment adopts advanced control systems and transmission devices to ensure the accuracy and clarity of the thermal transfer pattern.

Wide applicability: The roll-to-roll heat transfer machine is suitable for thermal transfer of a variety of materials, such as polyester fiber, paper, plastic, etc., to meet the needs of different fields.

Energy saving and environmental protection: By optimizing the thermal transfer process and heating system, the equipment can reduce energy consumption and emissions, and meet environmental protection requirements.

Function

Thermal transfer function: The roll-to-roll heat transfer machine can transfer pre-printed patterns to substrates to achieve pattern replication and personalized customization.

Temperature control: The equipment has a precise temperature control system, which can adjust the heating temperature according to the characteristics of the material and the requirements of thermal transfer to ensure the quality of thermal transfer.

Pressure regulation: By adjusting the pressure device, the equipment can adapt to the thickness and hardness of different materials to ensure the firmness and clarity of the thermal transfer pattern.

Speed control: The roll-to-roll thermal transfer machine has a speed regulation function, which can adjust the operating speed according to production needs and improve production efficiency.

Application field

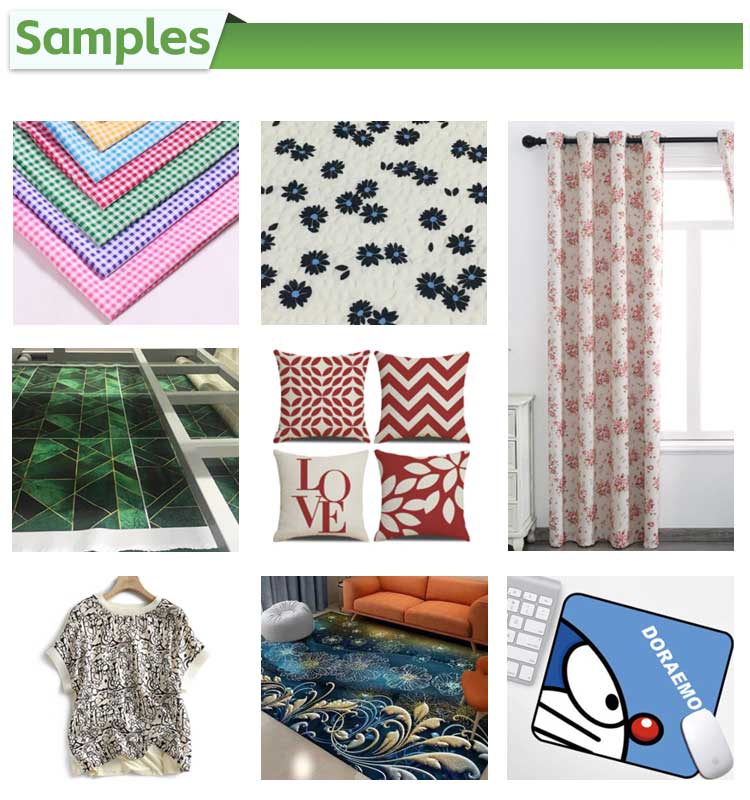

Textile industry: Roll-to-roll thermal transfer machines are widely used in the textile industry, such as T-shirts, clothing, towels and other products.

Packaging industry: The equipment can be used for thermal transfer of packaging materials, such as food packaging, gift packaging, etc., to improve the beauty and added value of the product.

Advertising industry: Roll-to-roll thermal transfer machines can be used for thermal transfer of advertising materials, such as outdoor advertising, promotional posters, etc., to achieve fast and efficient advertising production.

Personalization: The equipment can also be used in the field of personalized customization, such as mobile phone cases, cups, notebooks and other products. Printing patterns and texts to meet the personalized needs of consumers.

Maintenance and care

Daily cleaning: Regularly clean the surface and interior of the roll-to-roll thermal transfer machine, remove impurities such as oil, dust, etc., and keep the equipment clean and hygienic.

Lubrication and maintenance: Regularly lubricate the transmission device, bearings and other parts of the equipment to ensure smooth operation of the equipment and extend its service life.

Temperature detection: Regularly check the temperature controller and sensor of the heating system to ensure their normal operation and avoid abnormal temperature causing damage to the equipment or deterioration of the quality of thermal transfer.

Pressure detection: Regularly check the pressure gauge and sensor of the pressure device to ensure their normal operation and avoid abnormal pressure causing the firmness and clarity of the thermal transfer pattern to decrease.

Electrical inspection: Regularly check the wires, cables, electrical connectors and other parts of the electrical system to ensure that they are in good contact, without aging, breakage and other phenomena, to avoid electrical failures causing equipment shutdown or damage.

Precautions

Operation specifications: Operators should be familiar with the operating procedures and safety precautions of the roll-to-roll thermal transfer machine to ensure correct and safe operation of the equipment.

Material selection: Select appropriate materials and thermal transfer films to ensure the quality and firmness of the thermal transfer pattern.

Temperature control: According to the characteristics of the material and the requirements of thermal transfer, reasonably adjust the heating temperature to avoid excessively high or low temperatures causing deterioration of the quality of thermal transfer.

Pressure adjustment: According to the thickness and hardness of the material, the pressure device should be reasonably adjusted to ensure the firmness and clarity of the heat transfer pattern.

Equipment inspection: Before starting the equipment, the equipment should be fully inspected to ensure that all components are normal and intact to avoid equipment failure leading to production interruption or damage.

Safety protection: When operating the roll-to-roll heat transfer machine, appropriate personal protective equipment such as gloves, goggles, etc. should be worn to prevent injuries during operation. At the same time, direct contact with dangerous areas such as high temperature and high pressure should be avoided to avoid accidents such as burns and electric shocks.

Maintenance: Regularly maintain and maintain the roll-to-roll heat transfer machine to keep the equipment clean and lubricated to ensure the normal operation of the equipment and extend its service life. At the same time, an equipment maintenance file should be established to record the maintenance and troubleshooting of the equipment for subsequent analysis and improvement.

Roll To Roll Heat Transfer Machine is an efficient, precise and widely applicable heat transfer equipment. Through reasonable operation and maintenance, the normal operation of the equipment and the extension of its service life can be ensured, while improving production efficiency and product quality. It has broad application prospects and development potential in the textile industry, packaging industry, advertising industry, and personalized customization.

Catalogue

Machine Details