Power Rotary Thermal Transfer Sublimation Roller Heat Press Machine

Product Description

The Power Rotary Thermal Transfer Sublimation Roller Heat Press Machine is a type of industrial machine used for large-scale heat transfer printing. It is designed to transfer heat and pressure onto a substrate, such as fabric or paper, using a heated roller that is coated with a heat transfer material.This type of 420mm Roller Transfer Machine is commonly used in the textile and garment industry for printing designs onto fabrics, as well as in the production of signage and promotional materials. The roller design allows for continuous printing of large quantities of material, making it a popular choice for high-volume printing applications.

The Double Roller Heat Transfer Machine operates by using a heat transfer material, which is applied to the surface of the substrate, and then transferred to the substrate using heat and pressure from the roller. This process results in a permanent and durable print that is resistant to fading, cracking, and peeling.

Overall, the Power Rotary Thermal Transfer Sublimation Roller Heat Press Machine is a powerful and efficient tool for large-scale heat transfer printing, making it an essential piece of equipment for many businesses in the printing and manufacturing industries.

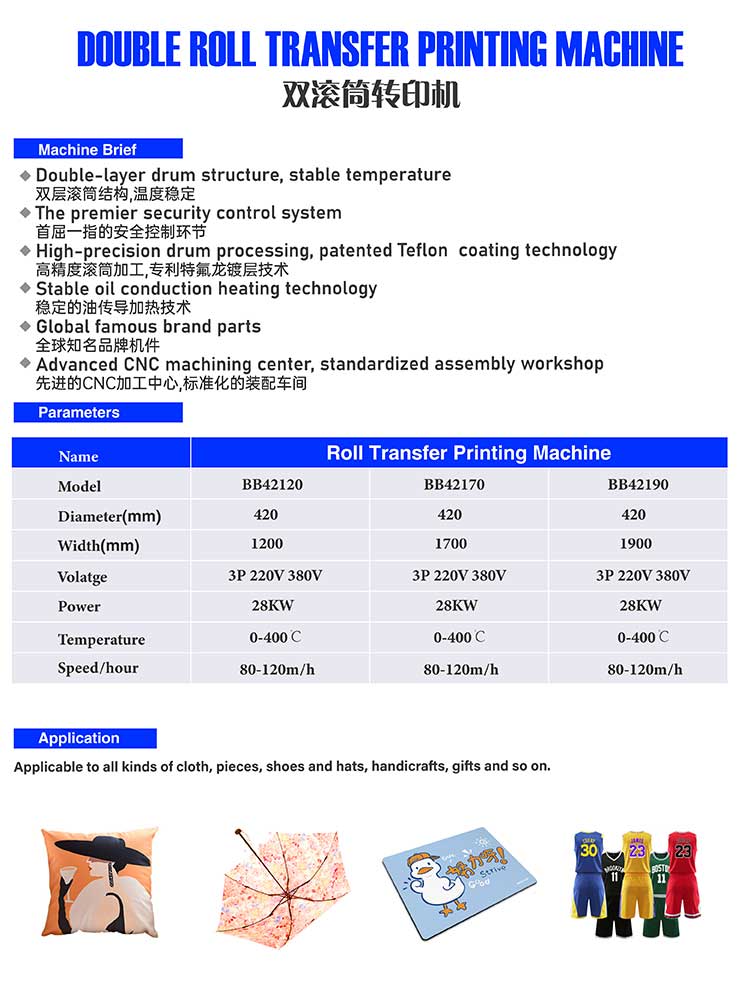

Parameter

| Name | Heat transfer sublimation machine |

| Model | BB42120 |

| Diameter | 420MM |

| Width | 1200MM |

| Voltage | 110v / 220v / 380V |

| Power | 25kw |

| Temperature | 0-400°C |

| Speed/hr | 80-120m/h |

| Packing size | 3.68*2.6*1.3m |

| N.W | 1400kg |

Catalogue

Machine Brief

Double-layer drum structure, stable temperature

The premier security control system

High-precision drum processing, patented Teflon coating technology

Stable oil conduction heating technology

Global famous brand parts

Advanced CNC machining center, standardized assembly workshop

Advantages of Sublimation Roller Heat Press Machine

Due to its roller design, the Sublimation Roller Heat Press Machine can continuously process large areas and roll materials, significantly improving production efficiency. Compared with traditional flat-bed heat transfer machines, it can complete more transfer tasks in a shorter time, which is very suitable for large-scale production, such as advertising fabrics, flags and clothing fabrics.

The Sublimation Roller Heat Press Machine is equipped with a precise temperature control system, usually using oil heating technology to ensure that the surface temperature of the roller is uniform and stable. This feature ensures that the pattern is clear and full every time it is transferred, and the transfer quality can be maintained consistently in every part of the fabric.

The Sublimation Roller Heat Press Machine is suitable for a variety of high-temperature resistant fabric materials, including polyester, nylon, flag cloth, sportswear fabrics, etc. This can not be limited to a certain product or material, and can flexibly meet the transfer needs of various different materials, so it is widely used in industries such as fashion clothing, home textiles, advertising displays, etc.

Through the sublimation process, the Sublimation Roller Heat Press Machine can achieve very fine patterns and color transitions, especially for designs that require rich colors and outstanding details. Therefore, this equipment is often used to produce high-quality image and logo printing, such as flags, tablecloths and other products.

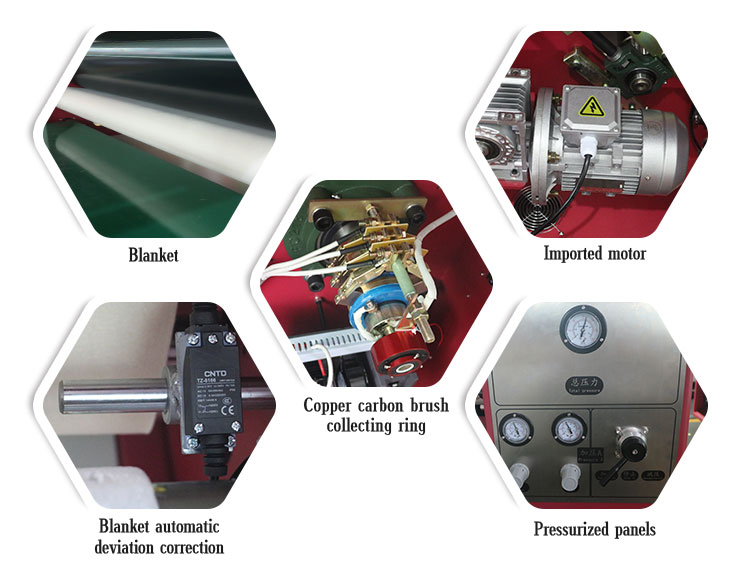

Details

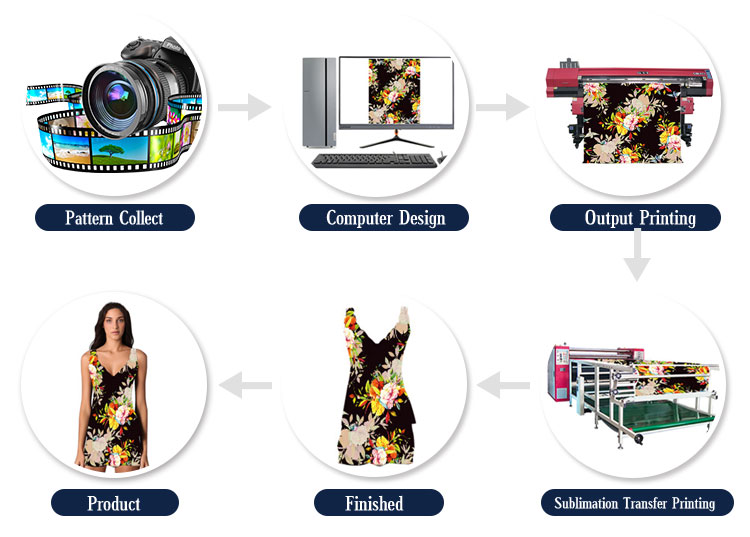

Process

Samples