It is mainly used to transfer dyes to fabrics through a heating process to achieve colorful and long-lasting patterns. This technology is widely used in the textile and clothing industry, such as custom clothing, sportswear and home textiles. Sublimation Printing machines are also used to create personalized promotional products, interior decorations, advertising logos and high-quality reproductions of art and photography.

Product Description

With its stable performance and high precision, the thermal transfer sublimation machine can accurately transfer the design pattern to various fabrics through thermal transfer technology, ensuring bright colors, clear details and durability. Whether it is used for custom clothing, sportswear, home textiles or advertising logos and artworks, this machine can provide excellent printing effects and consistent quality to meet the high standards of different customers.

Product Parameters

Model | ba61170 |

Diameter(mm) | 610 |

Width(mm) | 1700mm |

Volatge | 380v |

Power | 45kw |

Temperature | 0-400℃ |

Noise | 30qb |

Speed/hour | 160-220m/h |

Weight(kg) | 2500 |

Advantages of thermal Sublimation Printing Machine:

Stable performance: The use of high-quality components and advanced technology ensures the stability of the machine during long-term operation, reduces downtime and improves production efficiency.

High precision: The roller diameter is 610mm and the width is 1700mm, which can achieve precise thermal transfer, ensuring clear pattern details, bright and uniform colors.

High efficiency: The machine can reach a speed of 160-220 meters per hour, which is suitable for large-scale production needs, significantly improves production efficiency, and meets the high standards of different customers.

Wide temperature range: The temperature range is 0-400°C, which can adapt to a variety of fabrics of different materials, ensuring that the printing effect is long-lasting and durable.

Low noise: The operating noise is only 30dB, providing a quiet working environment, improving the comfort and work efficiency of operators.

High power output: The power of 45kW ensures fast heating and stable temperature control, further improving the printing quality and production speed.

Strong adaptability: Suitable for a variety of fabric types and thicknesses, widely used in textiles, clothing, home textiles, advertising logos and artworks.

Sturdy and durable: The machine weighs 2500kg, has a solid structure, a long service life, and can withstand high-intensity production tasks.

In general, the BA61170 thermal sublimation printer has become an ideal choice in the textile printing industry with its stable performance, high precision, high efficiency and versatility.

Selling Point

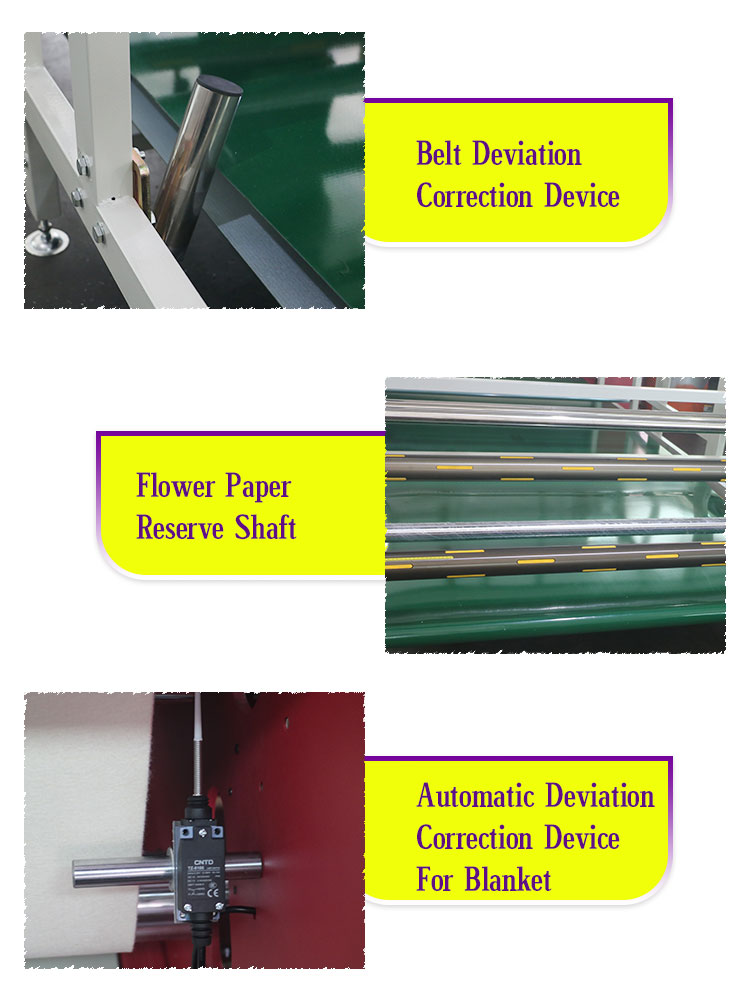

Decal paper storage shaft: The machine is equipped with a decal paper storage shaft, which can easily store and manage decals, improve production efficiency and reduce downtime.

Belt offset correction device: The built-in belt offset correction device can ensure that the conveyor belt maintains the correct position during operation, avoids offset, and ensures the accuracy and consistency of printing.

Blanket automatic offset correction device: The blanket automatic offset correction device can monitor and correct the offset of the blanket in real time, ensuring that the blanket remains flat during the printing process and avoiding printing quality problems caused by offset.

Product Details

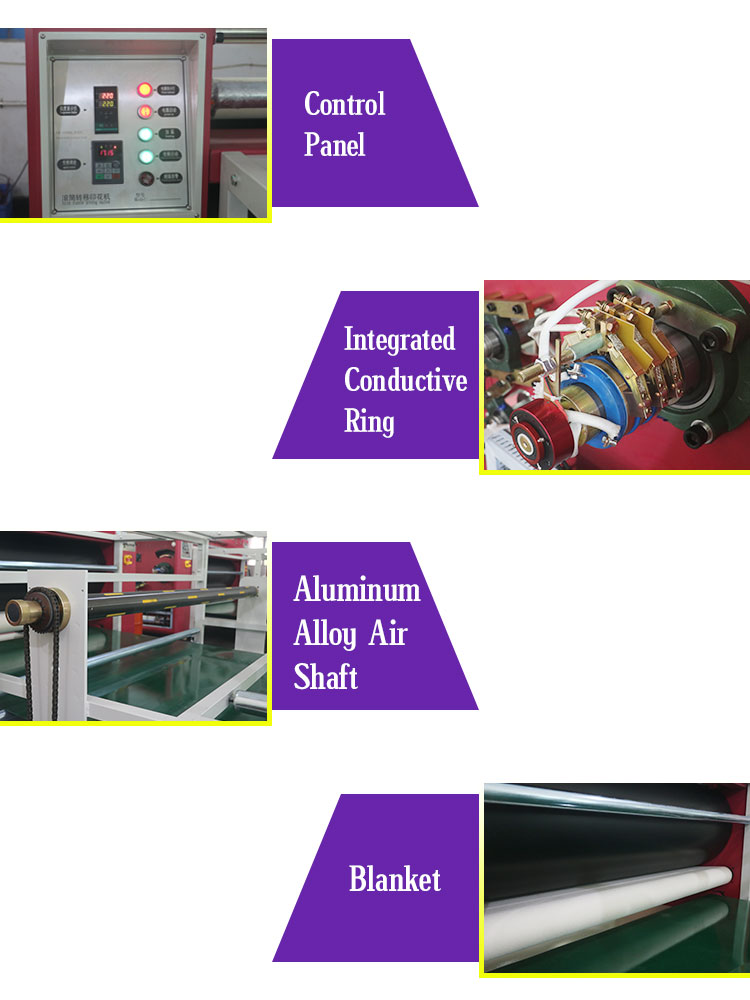

Control panel: The intuitive and easy-to-use control panel provides precise operation control, allowing users to easily set and adjust various parameters to ensure the smooth progress of the printing process.

Integrated conductive ring: The machine is equipped with an integrated conductive ring to ensure the stability and reliability of power and signal transmission, and improve the overall performance of the equipment.

Aluminum alloy air shaft: The high-strength aluminum alloy air shaft is lightweight and durable, ensuring stability and reliability during long-term operation.

Blanket: High-quality blankets with excellent heat and wear resistance ensure consistency and high-quality output during the printing process.

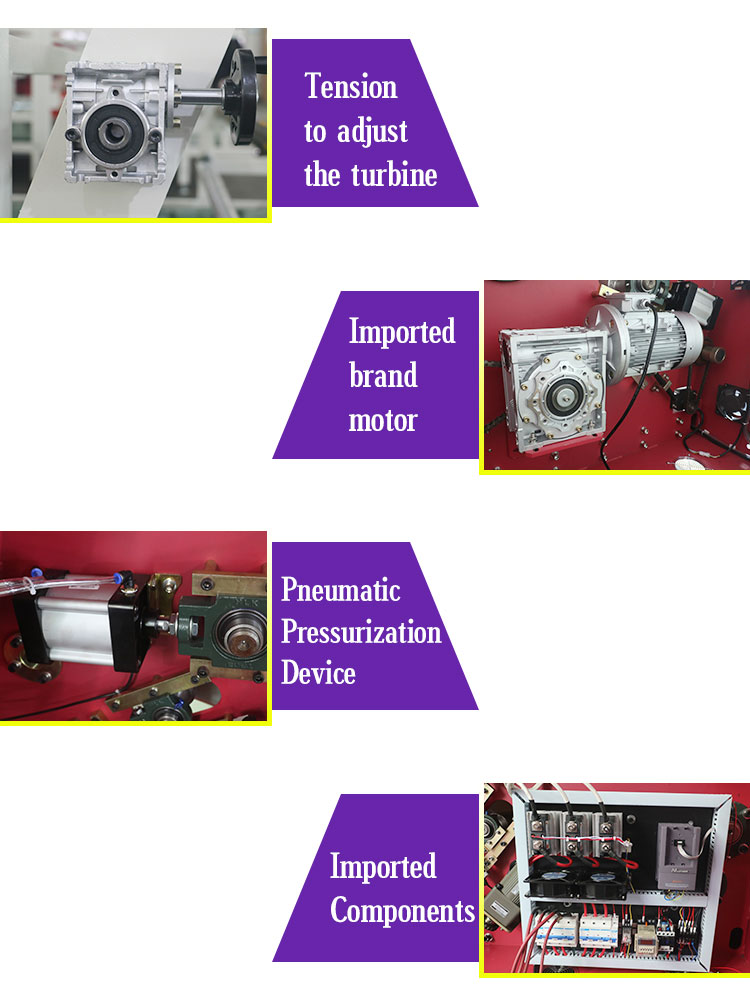

Tension adjustment turbine: The advanced tension adjustment turbine system can accurately control the tension of the blanket to ensure accurate and consistent patterns during the printing process.

Imported brand motor: Equipped with high-performance imported brand motors to ensure stable operation, low noise and long life of the machine.

Pneumatic pressurization device: The pneumatic pressurization device can provide uniform and adjustable pressure to ensure the best pattern transfer effect during the printing process.

Imported components: The key components used in the machine are all imported brands, ensuring the high quality and long-term durability of the equipment.

Printing Process

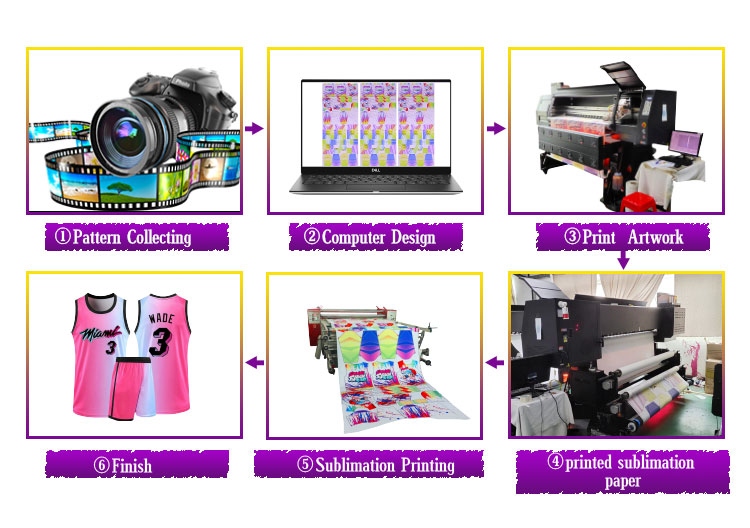

Printing process of Sublimation Printing Machine:

Computer design: Use professional design software to create and edit patterns and designs on the computer to ensure the accuracy of the design and meet customer needs.

Pattern production: Print the designed pattern on sublimation paper, and use high-quality printing equipment to ensure the clarity of the pattern and the vividness of the color.

Sublimation printing: Put the printed sublimation paper and fabric into the sublimation printing machine together, and transfer the dye from the paper to the fabric through high temperature heating and pressure. The BA61170 printing machine can provide uniform temperature and pressure to ensure the accurate transfer of the pattern.

Pattern collection: After printing, the fabric is taken out of the machine, inspected and sorted to ensure that each finished product meets high quality standards.

Finished product: The printed fabric is post-processed, including cutting, sewing and packaging, to make the final finished product, such as custom clothing, home textiles, etc.

This process ensures that every step from design to finished product can be completed efficiently and with high quality. The BA61170 sublimation printing machine plays an important role in every link, ensuring the excellent quality of the final product.

Samples

Sublimation Printing Machine For Calico And Roll Fabric are ideal for businesses and individuals who require high-quality and reliable printing output without the need for manual adjustments or intervention. If you are interested in our products, please contact us.