The Digital Heat Transfer Label Printing Machine is designed for high-quality, customizable label production using heat transfer technology. It allows for precise and efficient printing of labels on various substrates, such as fabrics, plastics, and metals, by transferring digital designs using heat and pressure.This machine is commonly used in industries such as apparel, promotional products, and packaging, offering flexibility for creating detailed, durable labels with vibrant colors and intricate designs. Its digital capabilities enable on-demand printing and quick turnaround times, making it ideal for both small and large-scale production runs.

Machine Display

Advantage

Complex Roller Heating technical, Enquire heating more fast and stability

Independent welding table, easy to install and remove;

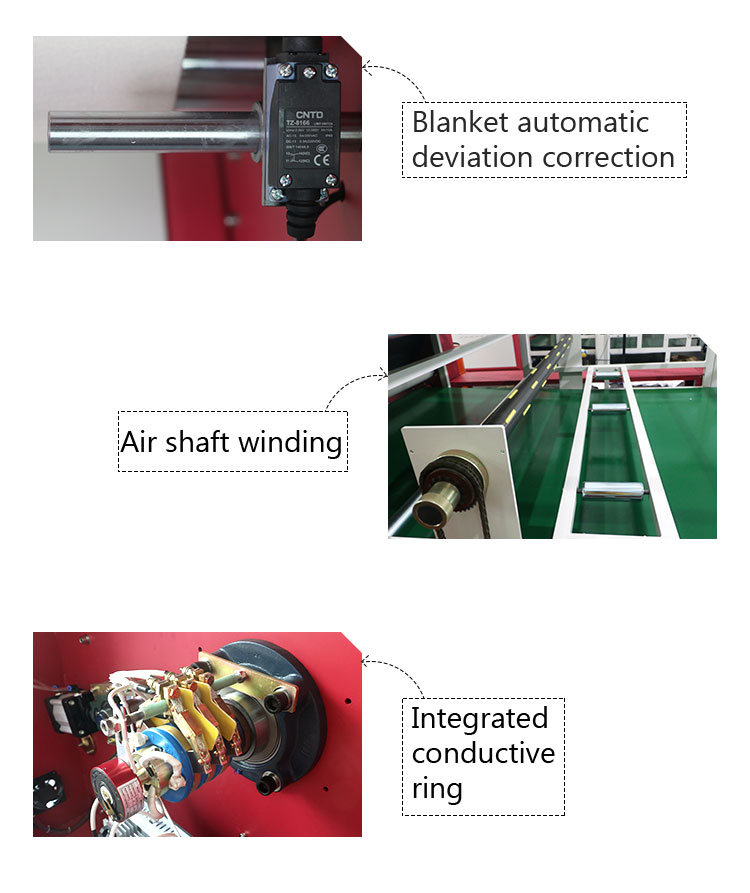

Air up the shaft roller, precise tension control, to ensure that the delivery of paper neat;

Anti-pinch device to ensure safe operation;

Microcomputer operation panel, simple and reliable;

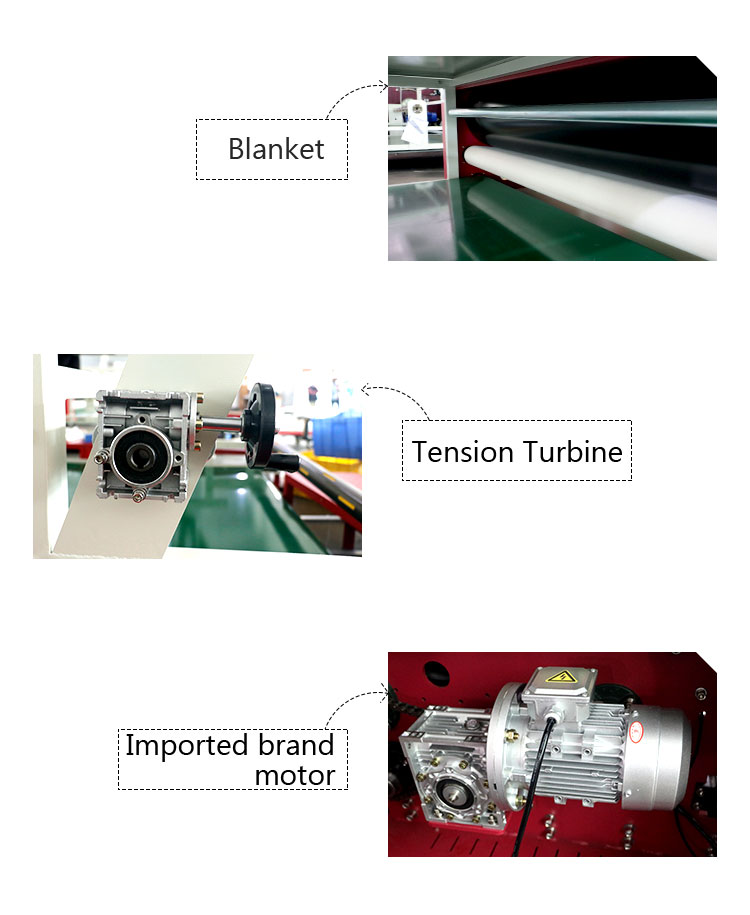

High burning point conveyor blankets, flame retardant performance; blanket thickness uniformity, the transfer effect is good;

Teflon coating heating roller, effectively prevent electrostatic interference in the transfer process, roller temperature is small;

Roller with internal and external precision turning and grinding, uniform thickness, heat transfer stability;

Brand thermal oil, heat stable and uniform;

Adjustable blanket roller rack pressure mechanism, pressure adjustment is simple and convenient;

Independent pneumatic booster agencies to ensure high - pressure environment transfer, to achieve the transfer of color thousands;

Brand electrical components, long life, low failure rate;

latest collector ring signal transmission, high stability and long life;

PVC conveyor belt, isolation paper reel, ribbon drive shaft speed can be independent and flexible adjustment;

Independent blanket correction structure;

Precise temperature control system, the temperature difference in the range of 5 degrees;

Tension adjustment structure, to ensure that the cloth and paper transfer process of tension balance.

Parameters

| Model | Ba61120 |

| Diameter(mm) | 610 |

| Width(mm) | 1200 |

| Volatge | 380v |

| Power | 45kw |

| Speed/hour | 160-220m/h |

| Weight(kg) | 2200 |

Machine Details

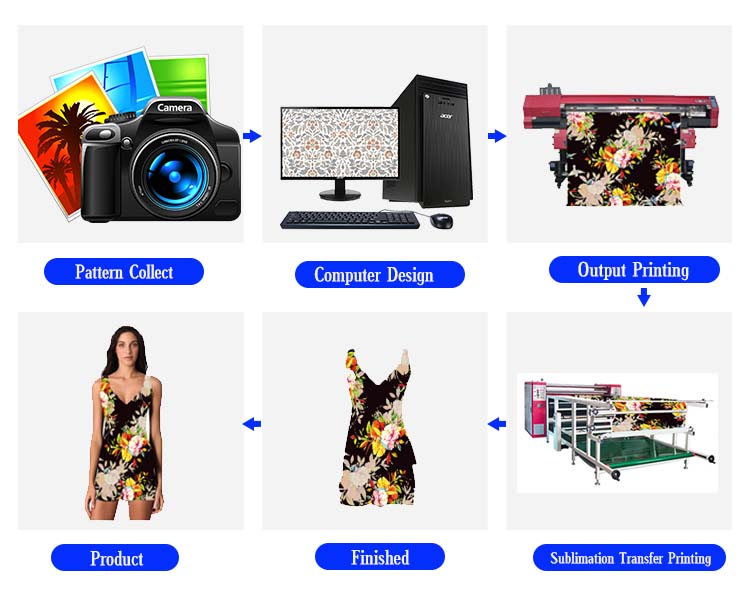

Printing Process

The printing process of a Digital Heat Transfer Label Printing Machine typically involves several key steps:

Design Preparation:

Create or import a digital design using graphic design software. This design is often prepared in high resolution and in the appropriate color profile for printing.

Printing the Transfer Film:

The digital design is printed onto a special heat transfer film or paper using a digital printer. The printer uses specialized inks that are formulated to adhere well to the transfer medium and withstand the heat transfer process.

Pre-Press Setup:

The printed transfer film is loaded into the heat transfer machine. The substrate (e.g., fabric, plastic, or metal) onto which the label will be transferred is also prepared and positioned correctly.

Heat Transfer Application:

The heat transfer machine applies heat and pressure to the transfer film and substrate. This process typically involves placing the printed transfer film onto the substrate and then applying heat (usually between 350°F to 400°F or 175°C to 205°C) and pressure using a heat press or heat transfer machine. The specific temperature, time, and pressure settings vary depending on the material being used.

Cooling and Peeling:

After the transfer is complete, the substrate is allowed to cool. Once cooled, the transfer film is carefully peeled away, revealing the printed label transferred onto the substrate.

Quality Check:

The final product is inspected for quality to ensure that the label is clear, vibrant, and correctly adhered. Any defects or issues are addressed before the labels are packaged or shipped.

This process ensures that digital designs are accurately and consistently transferred onto various surfaces, producing high-quality, durable labels.

Sample