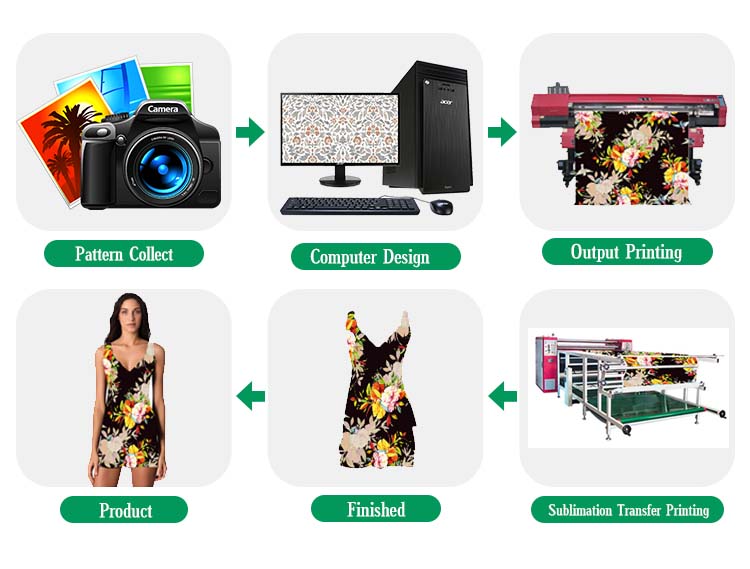

Roll To Roll Heat Transfer Press Machine is mainly used to transfer patterns or prints from transfer paper or film to continuous materials such as fabric, leather, non-woven fabrics, etc. by heat pressing.

This equipment is commonly used in the textile, clothing, household goods and advertising industries. It is suitable for mass production and can achieve large-area and efficient pattern transfer, ensuring bright colors and clear patterns.

Machine Display

Advantage

Complex Roller Heating technical, Enquire heating more fast and stability

Independent welding table, easy to install and remove;

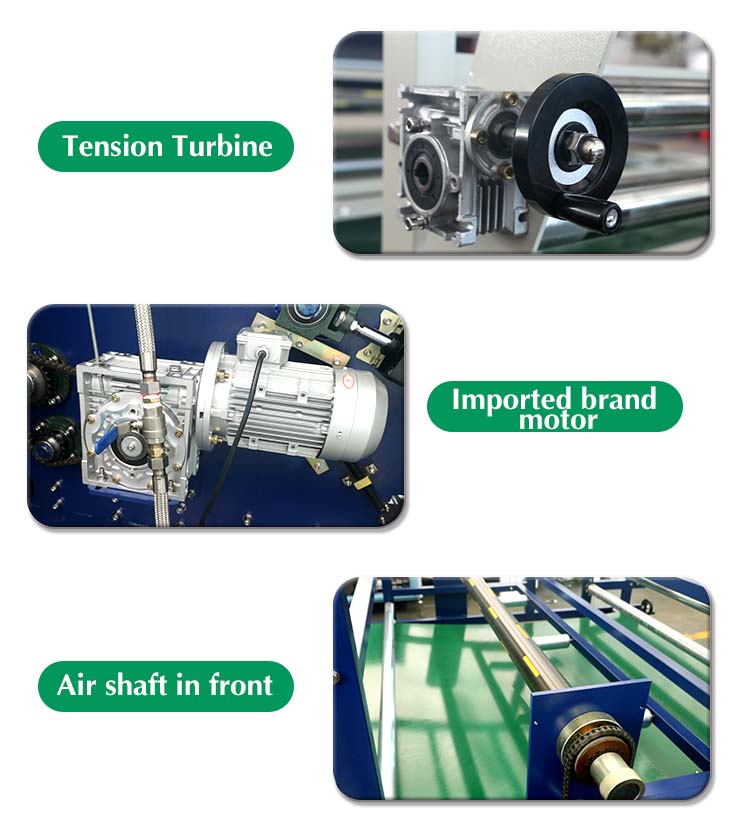

Air up the shaft roller, precise tension control, to ensure that the delivery of paper neat;

Anti-pinch device to ensure safe operation;

Microcomputer operation panel, simple and reliable;

High burning point conveyor blankets, flame retardant performance; blanket thickness uniformity, the transfer effect is good;

Teflon coating heating roller, effectively prevent electrostatic interference in the transfer process, roller temperature is small;

Roller with internal and external precision turning and grinding, uniform thickness, heat transfer stability;

Brand thermal oil, heat stable and uniform;

Adjustable blanket roller rack pressure mechanism, pressure adjustment is simple and convenient;

Independent pneumatic booster agencies to ensure high - pressure environment transfer, to achieve the transfer of color thousands;

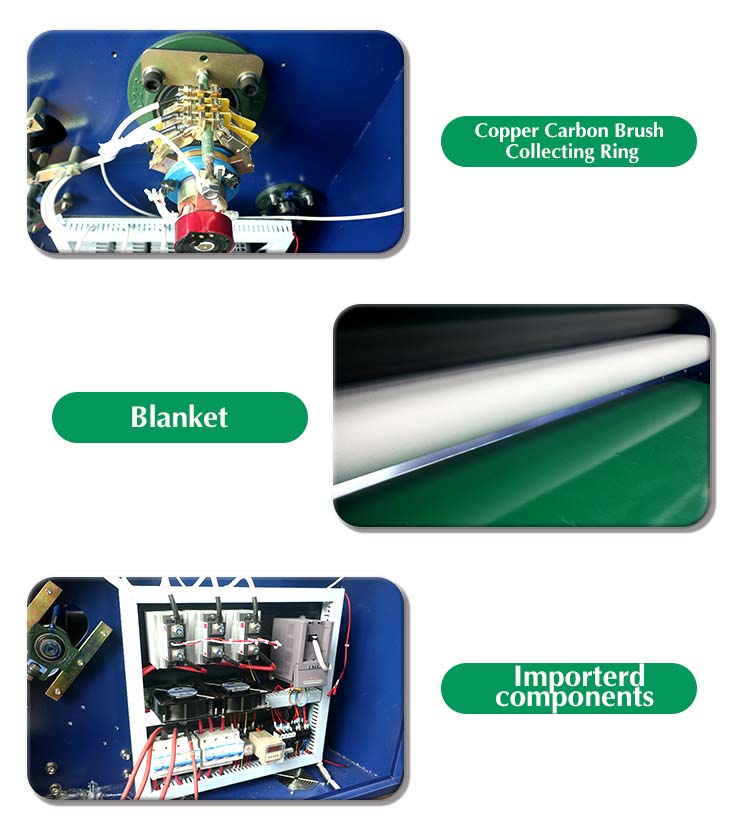

Brand electrical components, long life, low failure rate;

latest collector ring signal transmission, high stability and long life;

PVC conveyor belt, isolation paper reel, ribbon drive shaft speed can be independent and flexible adjustment;

Independent blanket correction structure;

Precise temperature control system, the temperature difference in the range of 5 degrees;

Tension adjustment structure, to ensure that the cloth and paper transfer process of tension balance.

Parameters

Model | BB61170 |

Diameter(mm) | 610 |

Width(mm) | 1700 |

Volatge | 380v |

Power | 42kw |

Speed/hour | 160-220m/h |

Weight(kg) | 2500 |

Machine Details

The following is a detailed introduction of the machine:

Copper Carbon Brush Collecting Ring:

The copper carbon brush collecting ring is used to transmit current and ensure that the machine maintains a stable current supply during operation. The use of this component helps to increase the service life of the machine, reduce brush wear, and ensure efficient transmission of electrical energy during the transmission process, so that the machine can maintain good performance during long-term continuous operation.

Blanket Imported Components:

The machine is equipped with imported blanket components. Blankets are a vital part of the thermal transfer process and can evenly distribute pressure and heat during heating and pressing. The use of imported blankets improves the efficiency of heat conduction and has the characteristics of high temperature resistance and wear resistance, ensuring the quality and details of the transferred pattern.

Tension Turbine:

The tension turbine is designed to control the tension of the material so that the material maintains appropriate tightness during the transfer process. This design can prevent the material from wrinkling or misalignment and ensure accurate transfer of the pattern. The stability and precise control ability of the tension turbine make the entire production process smoother and more efficient.

Imported Brand Motor: The machine uses an imported brand motor, which provides strong power support and stable operation. The imported motor not only ensures the durability and long service life of the machine, but also improves energy efficiency and reduces energy consumption. This high-performance motor can ensure stable operation in a high-speed production environment.

Air Shaft in Front: The front air shaft is used for quick loading and unloading of coils and is a key part of the machine operation. The use of the air shaft can significantly improve production efficiency and reduce downtime. At the same time, it also ensures the smooth operation of the coil in the machine, avoiding the sliding or loosening of the material, thereby improving the accuracy of the transfer.

The combination of these high-quality components makes the Roll To Roll Heat Transfer Press Machine show excellent performance in practical applications, suitable for high-intensity production needs, and ensures high quality and production efficiency of the product.

Printing Process

Sample

Application to all kinds of clothing,home texiles,handbags,umbrellas,straw mats,shoes and hats,

crafts,gifts,toys,advertising supplies,hot stamp,heat press machine,calender and so on.