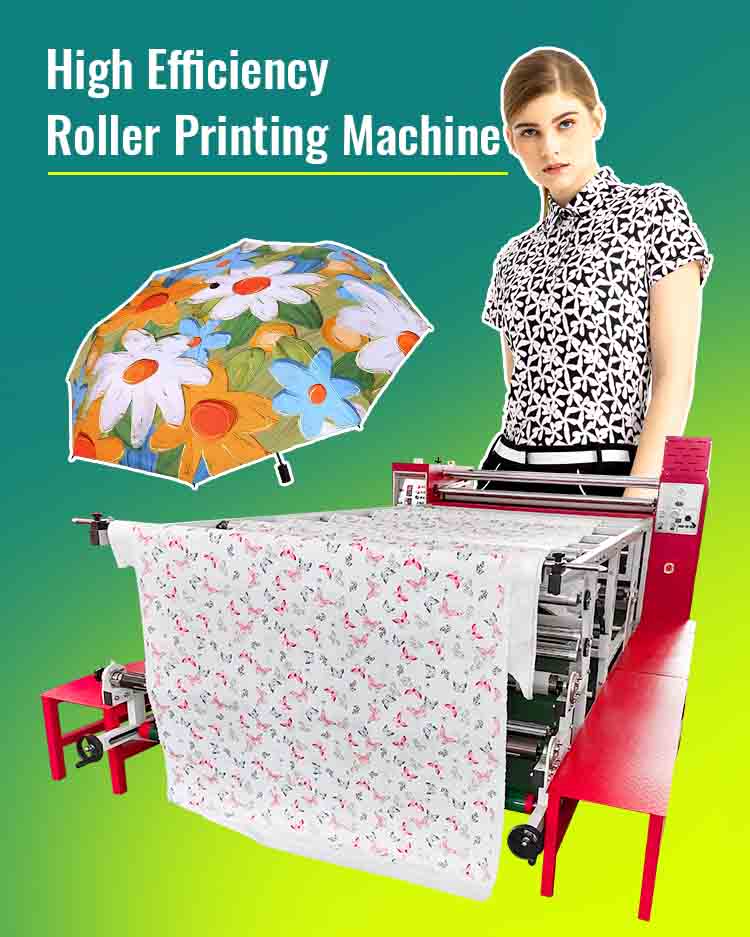

A Roller Sublimation Machine is used for high-quality, continuous sublimation printing on large-format fabrics and materials. It utilizes heat and pressure to transfer dye onto the substrate, creating vibrant, durable prints that are resistant to fading and wear. This machine is ideal for producing custom designs on textiles such as banners, flags, apparel, and home furnishings, making it a valuable tool for industries like fashion, advertising, and interior decoration.

Advantage

Complex Roller Heating technical, Enquire heating more fast and stability

Independent welding table, easy to install and remove;

Air up the shaft roller, precise tension control, to ensure that the delivery of paper neat;

Anti-pinch device to ensure safe operation;

Microcomputer operation panel, simple and reliable;

High burning point conveyor blankets, flame retardant performance; blanket thickness uniformity, the transfer effect is good;

Teflon coating heating roller, effectively prevent electrostatic interference in the transfer process, roller temperature is small;

Roller with internal and external precision turning and grinding, uniform thickness, heat transfer stability;

Brand thermal oil, heat stable and uniform;

Adjustable blanket roller rack pressure mechanism, pressure adjustment is simple and convenient;

Independent pneumatic booster agencies to ensure high - pressure environment transfer, to achieve the transfer of color thousands;

Brand electrical components, long life, low failure rate;

latest collector ring signal transmission, high stability and long life;

PVC conveyor belt, isolation paper reel, ribbon drive shaft speed can be independent and flexible adjustment;

Independent blanket correction structure;

Precise temperature control system, the temperature difference in the range of 5 degrees;

Tension adjustment structure, to ensure that the cloth and paper transfer process of tension balance.

Parameters

| Model | BB61170 |

| Diameter(mm) | 610 |

| Width(mm) | 1700 |

| Volatge | 380v |

| Power | 42kw |

| Speed/hour | 160-220m/h |

| Weight(kg) | 2500 |

Machine Details

Processing Workflow:

Preparation:

Blanket: Ensure the sublimation blanket is properly installed and in good condition. The blanket is crucial for even heat distribution and achieving high-quality prints.

Copper Carbon Brush: Check the copper carbon brush in the collecting ring to ensure it is functioning correctly. This component conducts electrical current to the heating elements.

Setup:

Air Shaft in Front: Position the air shaft at the front of the machine. This component helps in unwinding and feeding the material into the machine smoothly.

Printing:

Pressurization Device: Activate the pressurization device to apply consistent pressure to the material as it passes through the heated rollers. This ensures proper transfer of the sublimation dye onto the substrate.

Heat Transfer:

The material is fed between heated rollers where sublimation ink is transferred onto it under high temperature and pressure. The heat causes the dye to turn into gas and bond with the fabric.

Cooling and Finishing:

After the sublimation process, the material exits the machine and is cooled. The finished product is inspected for quality and any necessary adjustments or corrections are made.

Features:

High-Quality Print Transfer: Utilizes precise temperature control and pressure application to ensure vibrant, long-lasting prints.

Continuous Operation: Designed for large-format printing, allowing for continuous processing of materials for high-volume production.

Versatile Printing: Capable of printing on a variety of textiles and substrates, including banners, flags, and apparel.

Efficient Design: Includes components like the air shaft for smooth material handling and the pressurization device for consistent printing results.

Durable Components: Features robust parts such as the copper carbon brush and high-quality blanket to ensure longevity and reliable performance.

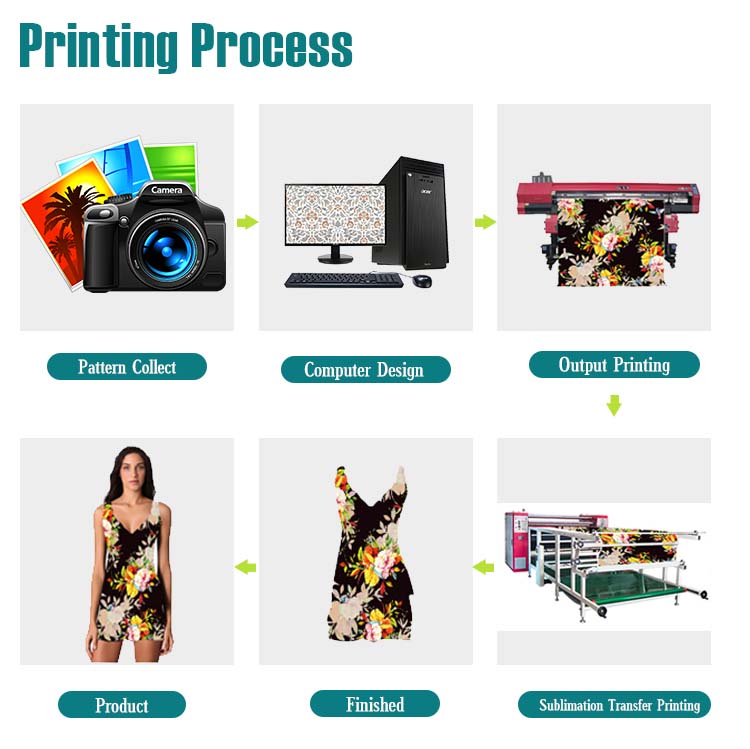

Roller Sublimation Machine: Processing Workflow

Computer Design:

Create or finalize the design pattern using computer design software. This design will be transferred onto the substrate.

Pattern Collection:

Collect and prepare the sublimation pattern, ensuring it is properly formatted for the printing process.

Output Printing:

Print the sublimation pattern onto transfer paper using a sublimation printer. The printed transfer paper will carry the dye that will be transferred to the fabric.

Sublimation Transfer Printing:

Feed the transfer paper and the substrate (fabric) into the Roller Sublimation Machine. The machine’s heated rollers apply high temperature and pressure to transfer the dye from the paper to the fabric.

Product:

After the sublimation process, the fabric with the transferred pattern is carefully processed and inspected.

Finished:

The final product is reviewed for quality, and any necessary finishing touches or corrections are made before packaging and delivery.

This workflow outlines the key steps involved in using a Roller Sublimation Machine for producing high-quality sublimated fabrics.

Sample

Application to all kinds of clothing,home texiles,handbags,umbrellas,straw mats,shoes and hats,crafts,gifts,toys,advertising supplies,hot stamp,heat press machine,calender and so on.