Sublimation Heat Transfer Printing Machines are widely used for transferring vibrant and detailed designs onto various materials, including fabrics, ceramics, and metals. These machines are essential in industries such as textile manufacturing, promotional products, and custom apparel. They provide high-quality, durable prints that are resistant to fading and cracking. As a leading supplier, Gaobao offers a range of sublimation heat transfer Printing Machines with advanced features like precise temperature control and high-speed operation, ensuring optimal performance for both small businesses and large-scale production facilities.

Machine Display

Advantage

Complex Roller Heating technical, Enquire heating more fast and stability

Independent welding table, easy to install and remove;

Air up the shaft roller, precise tension control, to ensure that the delivery of paper neat;

Anti-pinch device to ensure safe operation;

Microcomputer operation panel, simple and reliable;

High burning point conveyor blankets, flame retardant performance; blanket thickness uniformity, the transfer effect is good;

Teflon coating heating roller, effectively prevent electrostatic interference in the transfer process, roller temperature is small;

Roller with internal and external precision turning and grinding, uniform thickness, heat transfer stability;

Brand thermal oil, heat stable and uniform;

Adjustable blanket roller rack pressure mechanism, pressure adjustment is simple and convenient;

Independent pneumatic booster agencies to ensure high - pressure environment transfer, to achieve the transfer of color thousands;

Brand electrical components, long life, low failure rate;

latest collector ring signal transmission, high stability and long life;

PVC conveyor belt, isolation paper reel, ribbon drive shaft speed can be independent and flexible adjustment;

Independent blanket correction structure;

Precise temperature control system, the temperature difference in the range of 5 degrees;

Tension adjustment structure, to ensure that the cloth and paper transfer process of tension balance.

Parameters

Model | Ba61120 |

Diameter(mm) | 610 |

Width(mm) | 1200 |

Volatge | 380v |

Power | 45kw |

Speed/hour | 160-220m/h |

Weight(kg) | 2200 |

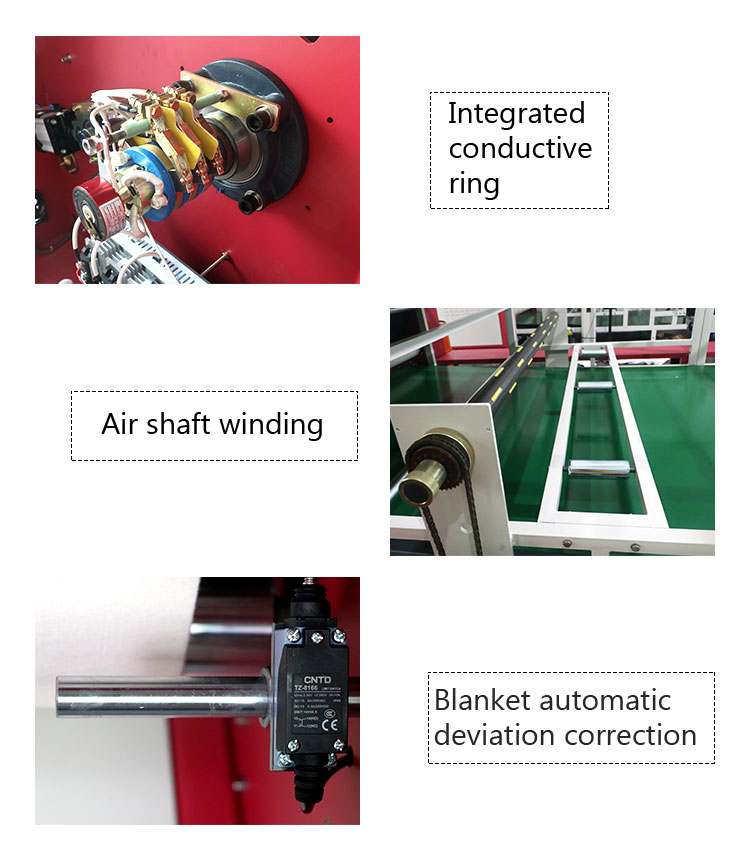

Machine Details

Comprehensive Conductive Rings: These ensure stable electrical conductivity throughout the printing process, minimizing the risk of interruptions and enhancing print quality.

Air Shaft Winding: The air shaft winding system provides secure and accurate material handling, essential for maintaining tension and alignment during high-speed operations.

Fully Automatic Deviation Correction: This feature automatically adjusts the material's position during printing, preventing misalignments and ensuring that the print remains perfectly centered on the substrate.

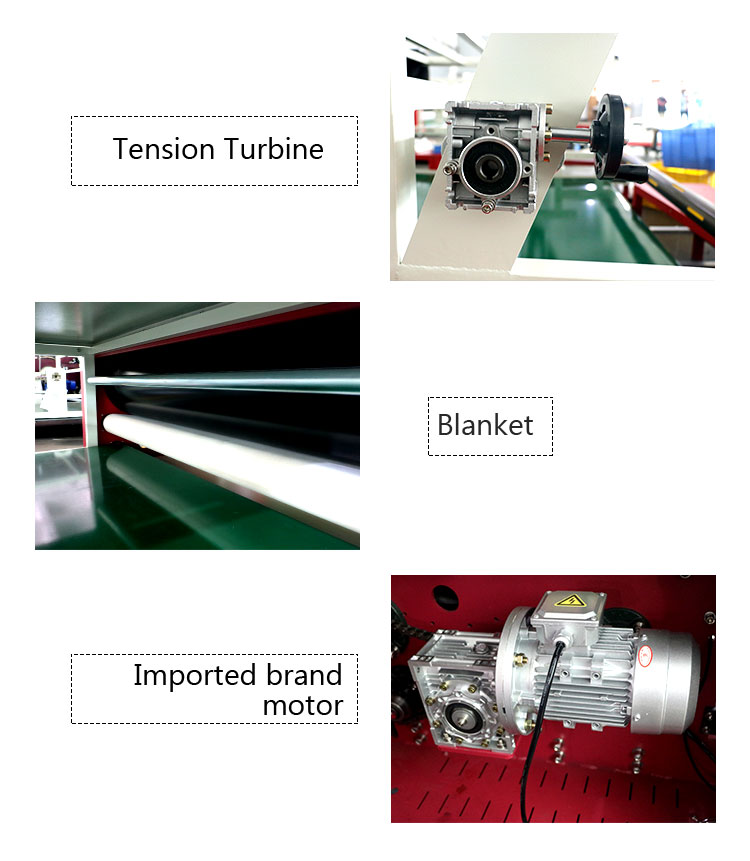

Tension Turbines: Tension turbines control the tension of the material being fed into the machine, ensuring consistent print quality by preventing wrinkles, stretching, or slack in the material.

Blanket: The machine's blanket is a crucial component that evenly distributes heat and pressure, ensuring the sublimation ink is properly transferred onto the material without any distortion or fading.

Imported Brand Motor: The use of high-quality motors from reputable brands ensures the machine operates smoothly and reliably, providing consistent power and reducing the likelihood of mechanical failure.

Expanded Functions:

Sublimation Heat Transfer Printing Machines play a crucial role in various industries. In the textile industry, they are used for producing custom apparel, sportswear, and home textiles with intricate designs and vibrant colors that are long-lasting and resistant to wear and tear. In the promotional products industry, these machines enable the creation of personalized items such as mugs, phone cases, and keychains, enhancing brand visibility and customer engagement. The precision and efficiency of these machines also make them ideal for large-scale production, where consistency and speed are paramount. Additionally, their advanced features, such as automatic deviation correction and tension control, ensure that even complex designs are accurately transferred, reducing waste and increasing overall productivity.

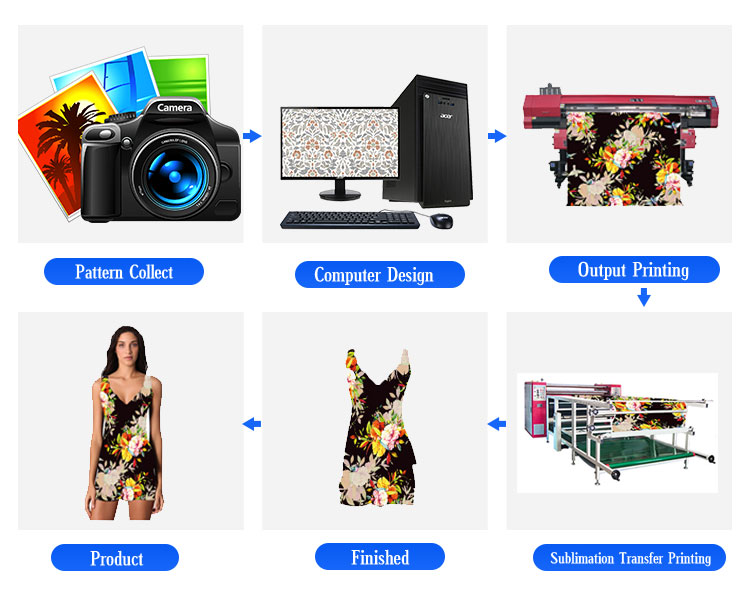

Printing Process

Sublimation heat transfer printing is a precise and intricate process that involves several key steps to ensure high-quality results. Here's a breakdown of the printing process:

The process begins with gathering the desired images, graphics, or patterns that need to be printed. These could be client-provided designs or custom artwork created for specific products.

Once the patterns are collected, they are digitized and refined using graphic design software. This step involves adjusting colors, scaling the design to fit the target product, and ensuring that the image resolution is optimal for printing.

The refined design is then printed onto a special sublimation paper using sublimation inks. These inks are formulated to turn into gas without passing through a liquid state when heated, enabling the transfer of the image onto the substrate.

The product, whether it’s a fabric, ceramic, or metal item, is prepared by ensuring it’s clean, smooth, and ready to receive the sublimation transfer. Any irregularities on the surface are addressed to avoid defects in the final print.

The sublimation paper with the printed design is placed onto the product. Under the heat press, the ink on the paper sublimates and bonds with the material of the product, resulting in a vibrant, durable print. The heat press ensures that the image is evenly transferred, with consistent color and sharp details.

After the transfer process is complete, the product is allowed to cool down, and any excess paper or material is removed. The finished product is then inspected for quality, ensuring that the print is accurate, durable, and meets the desired specifications.

This meticulous process allows for the production of high-quality, customized products that are resistant to fading and wear, making sublimation heat transfer printing a popular choice in various industries.

Sample