Sublimation Roller Heat Transfer Printing Machine is a device designed for high-volume and high-precision printing. It is mainly used to permanently print patterns onto fabrics, cloth or other material surfaces through heat pressing and transfer technology. It sublimates the dye on the transfer paper with pre-printed patterns and penetrates into the fibers of the target material through heat and pressure, thereby achieving colorful, wear-resistant and long-lasting pattern printing effects.

Main Features:

The roller design is suitable for continuous large-format material printing, greatly improving production efficiency. The temperature control system ensures accurate sublimation of dyes and provides high-definition and color-saturated patterns. It is not only suitable for various textile materials, but also can be applied to flags, banners, sportswear, home decoration and other fields. Made of high-quality materials, it ensures long-term and stable operation of the equipment, and is equipped with energy-saving functions to reduce energy consumption and meet environmental protection requirements.

Uses:

Sublimation Roller Heat Transfer Printing Machine is widely used in textiles, clothing, home textiles, banners, sportswear, fashion accessories and other fields. It is particularly suitable for printing patterns on large-format materials, such as bedding, curtains, carpets and flags, and can achieve mass production in a short time, ensuring clear patterns and lasting colors.

This type of machine is very suitable for companies that need to produce thermal transfer products efficiently and with high quality. Manufacturers can provide sales and support customized needs.

Machine Display

A Sublimation Roller Heat Transfer Printing Machine is an advanced printing device designed for transferring designs, patterns, and colors onto various materials using the sublimation process. It employs a roller system to ensure even heat distribution and facilitate the transfer of ink from a paper or fabric to the target material.

Advantage

Complex Roller Heating technical, Enquire heating more fast and stability

Independent welding table, easy to install and remove;

Air up the shaft roller, precise tension control, to ensure that the delivery of paper neat;

Anti-pinch device to ensure safe operation;

Microcomputer operation panel, simple and reliable;

High burning point conveyor blankets, flame retardant performance; blanket thickness uniformity, the transfer effect is good;

Teflon coating heating roller, effectively prevent electrostatic interference in the transfer process, roller temperature is small;

Roller with internal and external precision turning and grinding, uniform thickness, heat transfer stability;

Brand thermal oil, heat stable and uniform;

Adjustable blanket roller rack pressure mechanism, pressure adjustment is simple and convenient;

Independent pneumatic booster agencies to ensure high - pressure environment transfer, to achieve the transfer of color thousands;

Brand electrical components, long life, low failure rate;

latest collector ring signal transmission, high stability and long life;

PVC conveyor belt, isolation paper reel, ribbon drive shaft speed can be independent and flexible adjustment;

Independent blanket correction structure;

Precise temperature control system, the temperature difference in the range of 5 degrees;

Tension adjustment structure, to ensure that the cloth and paper transfer process of tension balance.

Parameters

| Model | Ba61120 |

| Diameter(mm) | 610 |

| Width(mm) | 1200 |

| Volatge | 380v |

| Power | 45kw |

| Speed/hour | 160-220m/h |

| Weight(kg) | 2200 |

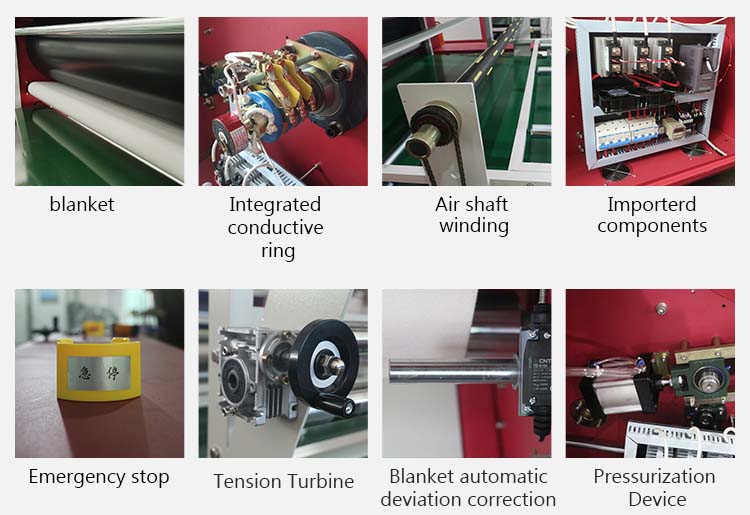

Machine Details

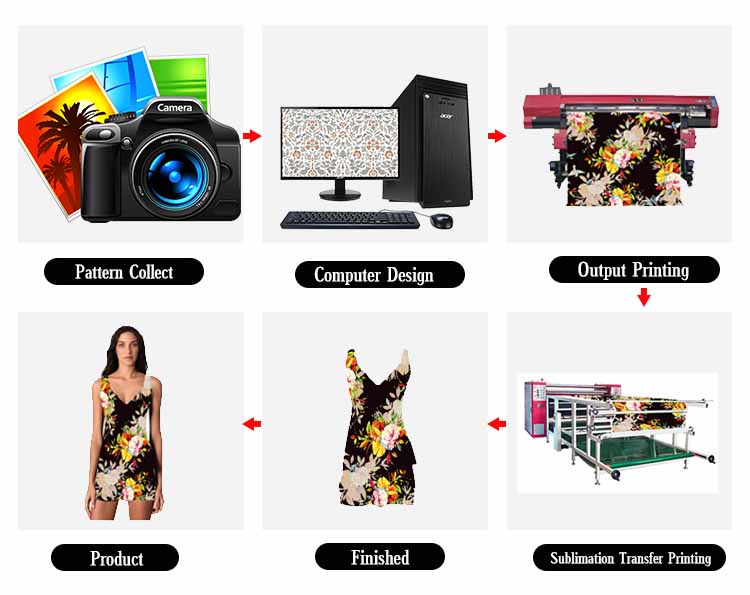

Printing Process

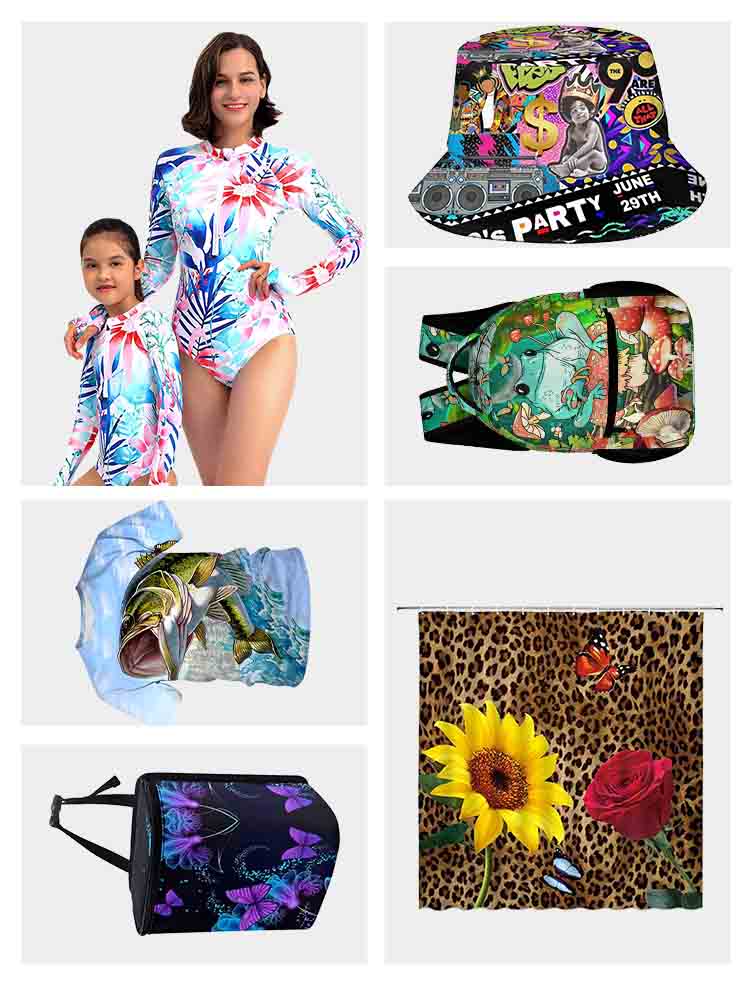

Sample

This printing technology is versatile and can be applied to a wide range of materials, including polyester fabrics, ceramic tiles, metals, and synthetic materials. Its ability to produce high-quality, full-color prints makes it popular for creating personalized apparel, promotional items, and customized products.

While highly versatile, sublimation printing may not be suitable for natural fibers like cotton. Additionally, intricate designs with fine details may pose challenges due to the nature of the sublimation process.

Safety precautions are crucial when operating such machinery. Users should follow manufacturer guidelines, wear appropriate protective gear, and ensure proper ventilation due to the release of gases during the sublimation process.