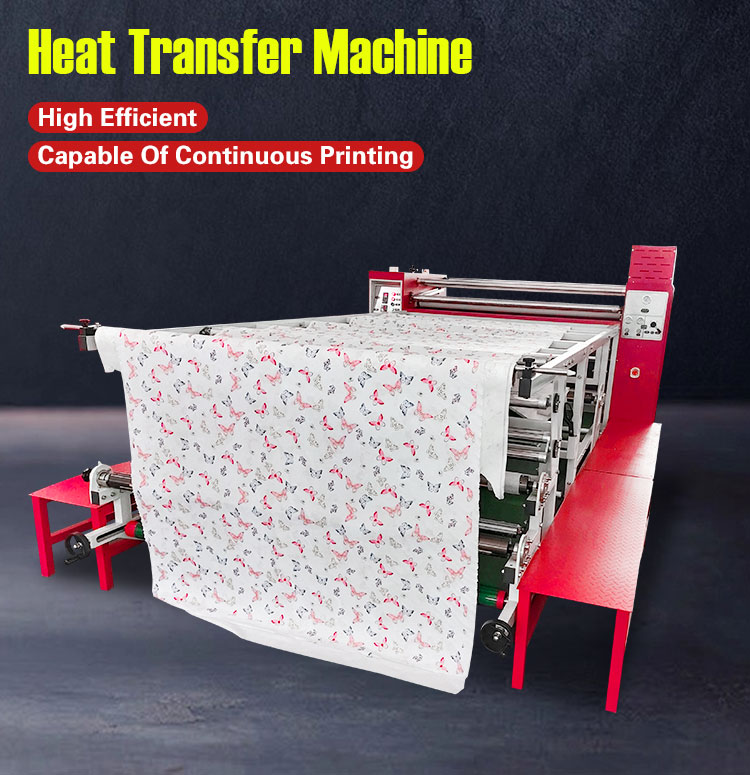

Roller Heat Press is an advanced heat transfer equipment widely used for pattern transfer on various fabrics and materials. This equipment combines high temperature and pressure to transfer the design pattern to the substrate through the continuous movement of the roller. It plays an important role in modern manufacturing, textile industry and personalized customization industry.

Equipment advantage

Roller transfer printing machine features

1. Adopt the "DuPont" blanket imported from the United States, the transfer effect is good, and the 800mm Roller Transfer Machine has a long service life.

2. Using seamless tube roller, roller outer circle/inner circle precision lathe, roller outer circle precision grinding, the transfer effect has no color difference.

3. The main wall panel is made of high-quality materials. Wire cutting, high precision and smaller error.

4. Imported speed-regulating and variable-frequency motor, the speed can be adjusted according to different materials for transfer.

5. Carbon brush conductive heating, conductive performance is more stable and safe.

6. Pneumatic pressurization/hydraulic pressurization function. The transfer effect is better, the color is deeper and more vivid.

7. The blanket is automatically separated. When the power is off or shut down, the blanket is automatically separated from the drum to better protect the blanket and prolong its life.

8. Conveyor belt transmission function. After the product is transferred, it is transported to the back of the work frame through the conveyor belt, which saves labor. The optional up and down conveying function is more efficient.

Product Parameters

| Model | bb80190 |

| Diameter(mm) | 800 |

| Width(mm) | 1900 |

| Volatge | 380v |

| Power | 60kw |

| Temperature | 0-400℃ |

| Noise | 30qb |

| Speed/hour | 280-600m/h |

| Weight(kg) | 3600 |

Product Details

Main technical features

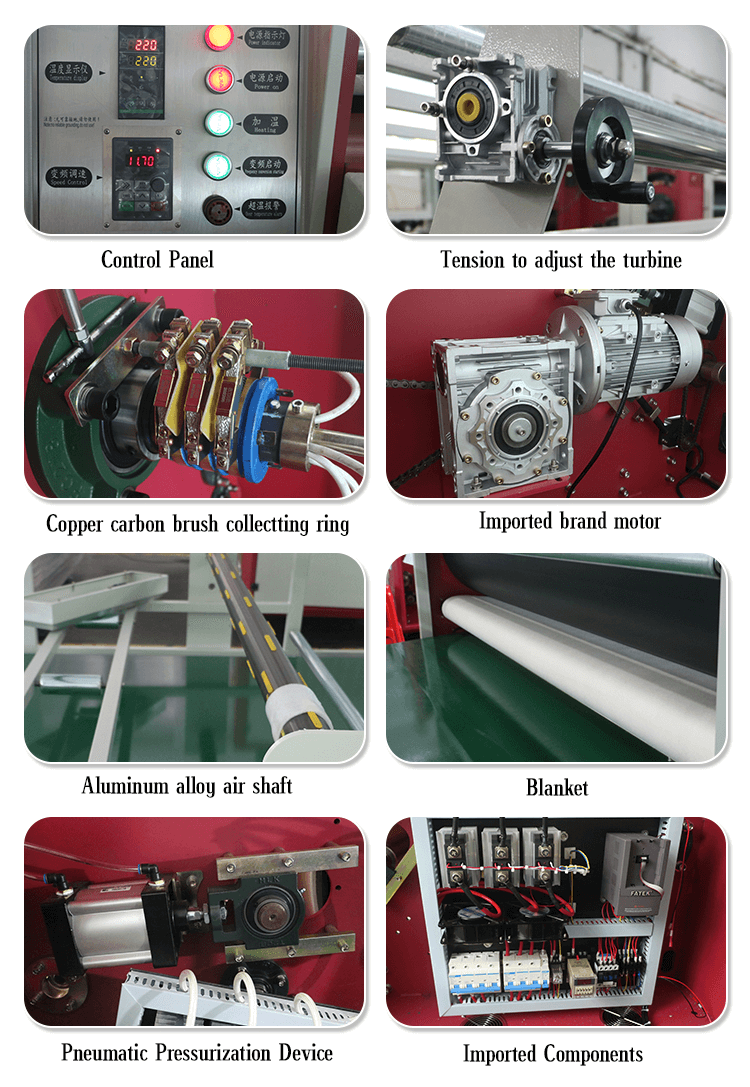

Control Panel

Functional description: The control center of the equipment, users can use the control panel to accurately adjust parameters such as temperature, pressure, speed, etc.

Advantages: Easy operation, high precision, ensuring the best transfer effect under different materials and process requirements.

Copper Carbon Brush Collecting Ring

Functional description: The collector ring is connected to the power supply through the copper carbon brush to provide a stable current for the equipment.

Advantages: Excellent conductivity, wear resistance, ensuring long-term stable operation of the equipment.

Aluminum Alloy Air Shaft

Functional description: Used for winding and unwinding materials, made of lightweight and high-strength aluminum alloy.

Advantages: Light weight, high strength, easy operation, corrosion resistance, and extended equipment life.

Pneumatic Pressurization Device

Functional description: Use pneumatic principles to pressurize the transfer process to ensure uniform transfer of the pattern.

Advantages: Stable pressure, wide adjustable range, adaptable to substrates of different thicknesses and materials, and improve transfer quality.

Tension to Adjust the Turbine

Functional description: Used to adjust the tension of the fabric or material during the transfer process to ensure that the material is flat and not deformed.

Advantages: Accurate adjustment, stable tension control, adapt to the requirements of different materials, and prevent material wrinkles and displacement.

Imported Brand Motor

Functional description: The core component that drives the equipment to operate, using imported brand motors to ensure sufficient power.

Advantages: Smooth operation, strong power, low noise, high energy efficiency, and extended equipment life.

Blanket

Functional description: Used as a heat transfer medium in the thermal transfer process, usually covering the surface of the roller.

Advantages: Uniform heat conduction, high temperature resistance, wear resistance, ensuring the clarity and uniformity of the pattern transfer.

Imported Components

Functional description: The key components used in the equipment, such as thermostats, sensors, etc., are all from internationally renowned brands.

Advantages: Reliable performance, high precision, strong durability, ensuring the overall quality and stability of the equipment.

Equipment advantages

Adopt advanced control system and high-quality components to ensure the stability and efficiency of the equipment for long-term operation.

Precise control

The control panel is easy to operate, and parameters such as temperature, pressure, speed, etc. can be precisely adjusted to meet the requirements of different materials and processes.

Versatile application

Suitable for thermal transfer of various fabrics and materials, such as clothing, home textiles, advertising banners, industrial fabrics, etc., with a wide range of applications.

Energy saving and environmental protection

Adopt imported brand motors and high-efficiency thermal conductive blankets to reduce energy consumption, improve thermal transfer efficiency, and meet environmental protection standards.

Easy maintenance

The equipment is reasonably designed, the key components are highly durable, and daily maintenance is simple, reducing maintenance costs and downtime.

High-quality transfer effect

Precise temperature and pressure control ensures the clarity, color vividness and durability of the pattern transfer, meeting the needs of high-quality printing.

With its advanced technical characteristics and excellent performance, Roller Heat Press has become an ideal choice for various thermal transfer applications. Whether you are engaged in clothing printing, advertising banner production, or personalized customization and industrial applications, Roller Heat Press can provide you with efficient and reliable solutions. By understanding its main technical features and advantages, you can better select and apply this equipment to improve production efficiency and product quality.

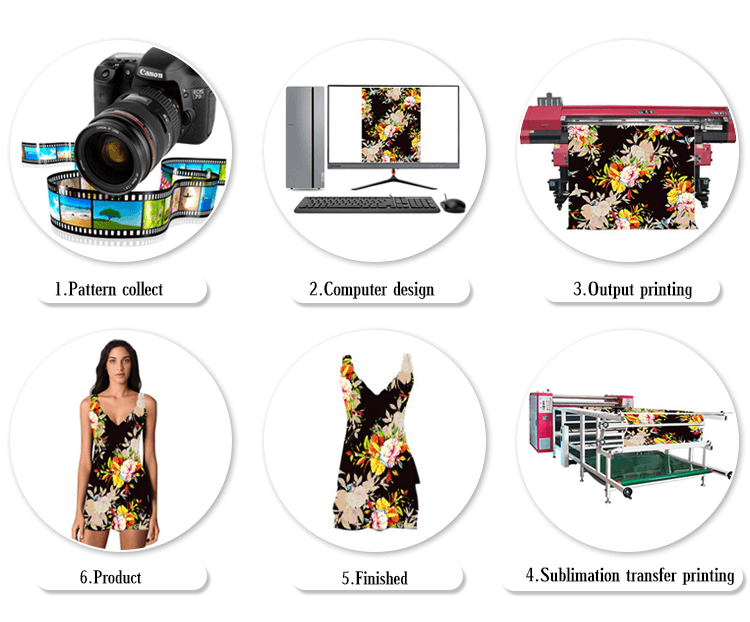

Printing Process

Samples

Roller Heat Press has a wide range of applications in textile printing. It can efficiently and accurately transfer designs to a variety of fabrics, including:

Apparel printing: Pattern transfers on T-shirts, dresses, sportswear, jeans, etc.

Home textiles: Printing of large-area fabrics such as sheets, quilt covers, pillowcases, curtains, etc.

Fashion accessories: Personalized design of small fabrics such as scarves, hats, gloves, etc.

Large logo and banner production

Roller Heat Press is particularly suitable for printing work on large-format materials, such as:

Advertising banners: High-quality banner production for commercial promotion and event publicity.

Logo signs: Pattern transfer for indoor and outdoor logos, ensuring bright colors and strong weather resistance.

Pattern transfer for industrial fabrics

In the industrial field, Roller Heat Press is used for pattern and logo transfers on various technical fabrics, such as:

Protective clothing: High-temperature transfer of special patterns or logos to ensure protection and beauty.

Filter materials: Used for logo transfer of industrial filters to improve product recognition.

Best printing machine limited belong to KC printing machine (Group) Limited, was established in 2009 and is located in the famous garment city "Dongguan - Humen "China. If you want to know more about our Roller Heat Transfer Machine products and other related information , please contact us, we look forward to your arrival.