Double layer roller heat transfer machine

- Product Item : BB61170

- Category:Double side -BB

- Weight:2800 KG

- power:42kw

- Voltage:110V / 220V / 380V

- Dimensions(L*W*H):4.65*2.82*1.5m

Large Format Rotary Sublimation Heat Transfer Printing Machine

| Model | BB61120 | BB61170 | BB61190 |

| Transfer width | 1200 mm (47'') | 1700 mm (47'') | 1900 mm (74.8") |

| Blanket size | 1250*3480*10 mm | 1750*3480*10 mm | 1950*3480*10 mm |

| heating Power | 21.6 KW | 27 KW | 27 KW |

| Heating media | Oil | ||

| Voltage | 3 phase 220 V/380 V | ||

| Number of heating elements | 18 | ||

| Diameter of drum | 610 mm | ||

| transfer speed | 0-380 m/h | ||

| Max. Temperature | 260 ℃ | ||

| Process Path | feeding in through the top of drum | ||

| Blanket separation method | manual | ||

| Sensor adjust the Blanket device | no | ||

| Function of roll-to-roll | yes | ||

| Function of piece-by piece | yes | ||

| Number of feeding rollers | 3 | ||

| Number of collection rollers | 2 | ||

| Number of air shaft | no | ||

| worktable | yes, without glass | ||

| Air compressor | needed, 1 P, (not include) | ||

| machine weight | 1100 KG | 1450 KG | 1800 KG |

| packing size | 2.12*1.19*1.6m | 2.75*1.3*1.7m | 2.95*1.3*1.9m |

| Worktable size | 3.5*1.5*0.9 m | 3.5*1.88*0.9 m | 3.5*2.05*0.9 m |

Product Advantages

- Complex Roller Heating technical, Enquire heating more fast and stability

- Independent welding table, easy to install and remove;

- Air up the shaft roller, precise tension control, to ensure that the delivery of paper neat;

- Anti-pinch device to ensure safe operation;

- Microcomputer operation panel, simple and reliable;

- High burning point conveyor blankets, flame retardant performance; blanket thickness uniformity, the transfer effect is good;

- Teflon coating heating roller, effectively prevent electrostatic interference in the transfer process, roller temperature is small;

- Roller with internal and external precision turning and grinding, uniform thickness, heat transfer stability;

- Brand thermal oil, heat stable and uniform;

- Adjustable blanket roller rack pressure mechanism, pressure adjustment is simple and convenient;

- Independent pneumatic booster agencies to ensure high - pressure environment transfer, to achieve the transfer of color thousands;

- Brand electrical components, long life, low failure rate;

- latest collector ring signal transmission, high stability and long life;

- PVC conveyor belt, isolation paper reel, ribbon drive shaft speed can be independent and flexible adjustment;

- Independent blanket correction structure;

- Precise temperature control system, the temperature difference in the range of 5 degrees;

- Tension adjustment structure, to ensure that the cloth and paper transfer process of tension balance.

• Excellent detail performance: It can clearly present fine patterns and texts, and it is very easy to achieve the reproduction of gradient colors. The breadth of its colors far exceeds that of multi-screen printing.

|

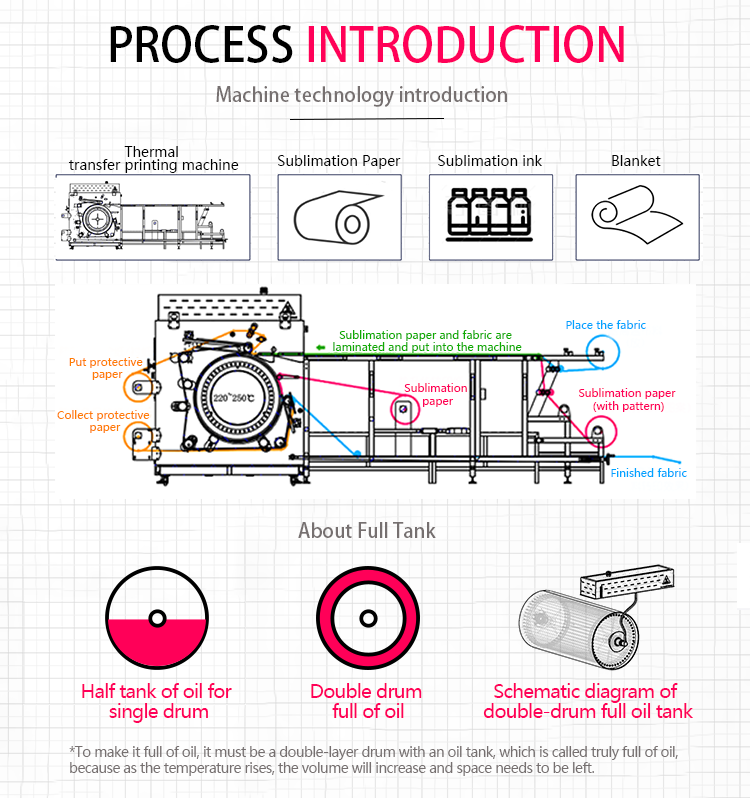

1. Why use oil conduction heating technology? Roller sublimation printing machine commonly adopt the design of heating tube inside the tube, heating tube power generation after heat, heat will be around the radiation, the use of heat transfer oil as a medium, high heat transfer efficiency and uniformity. The machine is running, the heat transfer oil is always located in the lower part of the roller and a steady stream of heat transfer to the roller surface. The heat-conducting oil has the property of resisting thermal cracking and chemical oxidation, has good heat-transfer efficiency, fast heat-dissipation and good thermal stability. A very high operating temperature is obtained at almost atmospheric pressure. Which can greatly reduce the high-temperature heating system operating pressure and safety requirements and improve the system and equipment reliability; But the heat transfer oil as a heat transfer medium also has a significant drawback: in the case of system leakage, heat conduction oil and flame encounter when there may be burning, so how to improve the heat transfer oil sealing space welding quality is the key technology of roller printing machine

|

|

2. What is the composite roller manufacturing technology? The heat transfer oil inside the roller is injected through the oil hole at the end and closed after injection. Because of the limitation of the injection method, the heat transfer oil in the roller can only occupy 50% of the inner cavity of the roller. Resulting in a difference in temperature between the upper roll and the lower roll. To this , Best printing machinery develop composite roller manufacturing technology. A sub-cylinder is welded inside the roll so that an annular region is formed between the sub-roll and the mother roll, which will occupy 75% of the cavity. The temperature difference between the upper and lower portions of the roll is remarkably reduced, and the transfer quality is further controlled. While the number of heating pipe immersed in heat transfer oil also increased, the efficiency of heating has also been significantly improved.

|

|

3. Roller diameter and the relationship between the speed of the machine? The same angular velocity, in different diameter will produce different line speed, the greater the diameter, the greater the line speed, which is to improve the transfer speed and efficiency of the most simple way. BEST printing machinery can manufacture 420mm, 610mm, 800mm or even larger diameter roller to meet the stringent requirements of the efficiency of the user. The larger the diameter of the roller is also easy to avoid frequent graphic splicing, reducing labor intensity, which is the user in recent years, the demand for large diameter roller causes soared. The greater the diameter of the roller, the higher the accuracy of the processing equipment, the current domestic production of more than 610mm diameter of the plant can be counted on one's fingers.

|

|

4. Roller transfer machine security?

Roller transfer machine is a high-temperature high-voltage high-power electrical equipment, if the manufacturing quality, but off, it is easy to cause fire, electric shock, or even hurt the accident. Best printing machinery for other domestic brands a number of security incidents, increasing the welding technology, leakage protection technology, rolling tips and a large number of advanced technology input and application of the domestic roller transfer machine security records have been Keep it low. BEST Printing machinery is the supremacy of the State Transfer Technical Standards Committee invited to discuss the standard of the only Pearl River Delta manufacturing units

|

|

5. Roller chrome-plated and Teflon-plated difference? Roller seamless steel pipe made by turning, in order to improve its surface finish, usually to be chrome-plated. Chromium layer smooth, high hardness, long life, especially for high-precision textile transfer, but because the chrome layer is smooth, the pressure of each roller once the line speed is different, easily caused by graphic distortion, color distortion quality problems, due to Electrostatic impact, chrome layer is also very easy to glue the textile debris, causing product graphics faint. To this end BEST printing machinery in the field of the introduction of roller manufacturing Teflon coating technology, Teflon coating with a certain degree of flexibility, easy to compensate for the pressure roller between the line speed difference, to avoid graphic distortion.

|

|

6. PVC conveyor belt and the difference between Teflon belt?

PVC conveyor belt with flat, smooth, not easy to heat, but easy to maintain the original state of textile after the transfer; Teflon conveyor belt with a network structure, easy to heat, but short life, light textiles easily lead to wrinkles. BEST printing machinery PVC conveyor belt mainly for the user to provide a variety of textile transfer convenience. Users can choose according to their own needs.

|

Certificate

COMPANY

Established in 2006;

Professional engaged in fabric printing field ;

Mainly Manufacture Roller sublimation transfer machine, Inkjet printer, Ribbon sublimation

transfer machine, Zipper sublimation transfer machine, Screen printing machine, Hot foil stamping machine Etc completely texile printing solution.

2019. Shanghai printing exhibition, Guangzhou printing exhibition, Shenzhen printing exhibition

Exhibition

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: lusa zhong

Mobile:+86 13829127980

Tel:+86 13829127980

Whatsapp:008613829127980

Email:sales@zsheatpress.com

Add:Fuma Road, Humen Town, Dongguan City, Guangdong Province, China