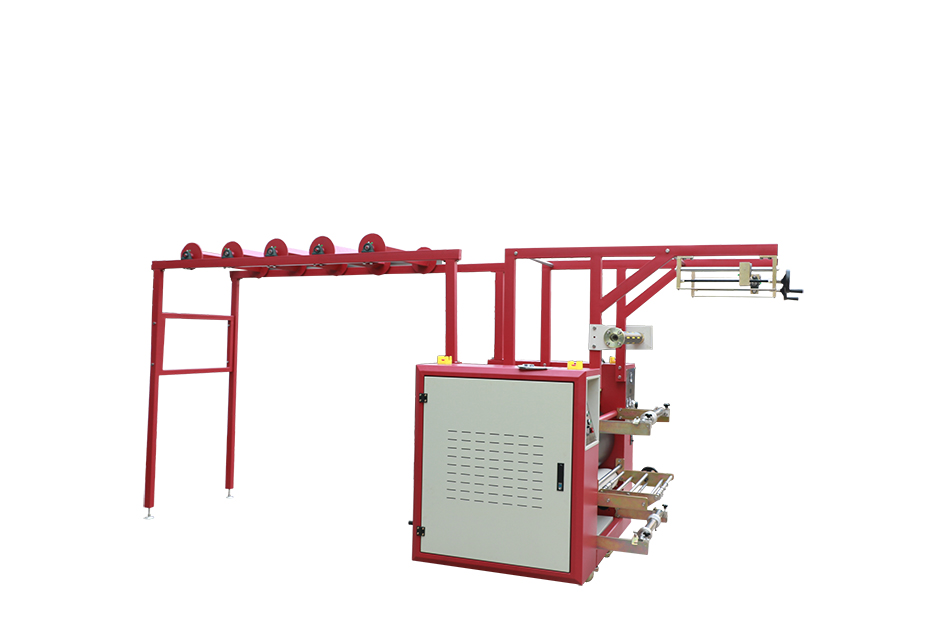

Down-feeding Ribbon Roller transfer machine

- Product Item : AB4260

- Category:Ribbon zipper heat transfer machine

|

AB42 Series Webbing sublimation heat transfer machine Technical parameter |

|||

|

Model |

AB4260 |

AB4290 |

AB42120 |

|

Roller Tape |

Simple Drum |

Simple drum |

Simple drum |

|

Roller size |

420*600mm |

420*900mm |

420*1200mm |

|

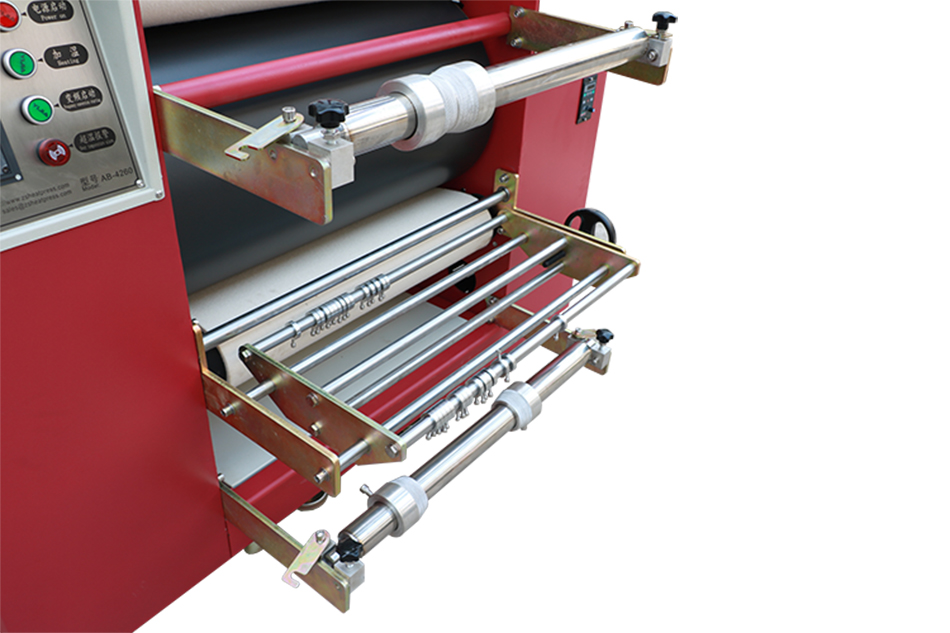

Roller diameter |

420mm |

420mm |

420mm |

|

Roller surface |

Coated with Teflon |

Coated with Teflon |

Coated with Teflon |

|

Transfer width |

600mm |

900mm |

1200 |

|

Transfer speed |

120-380m/h |

120-380m/h |

120-380m/h |

|

Diameter of shaft |

50mm |

50mm |

50mm |

|

Air swelling shaft |

2 |

2 |

2 |

|

The main machine dim |

1900*1000*1200 |

2500*1000*1200 |

2640*900*1200 |

|

The work table dim |

3500*1188*900 |

3500*1888*900 |

3500*2090*900 |

|

Installed dim |

4500*2500*1200 |

4500*2500*1200 |

|

|

Wooden box size |

2580*105*1330 |

2580*105*1330 |

|

|

Net weight |

520kg |

600kg |

750kg |

|

Gross weight |

550kg |

650kg |

800kg |

|

Blanket size |

175*2680*8 |

175*2680*8 |

1950*2680*8 |

|

Blanket separation method |

Manual |

Manual |

Manual |

|

Pressurized cylinder |

1set |

1set |

1set |

|

Air pressure |

su80*50 |

su80*50 |

su80*50 |

|

Pressurized way |

Pneumatic pressure |

Pneumatic pressure |

Pneumatic pressure |

|

Pressure shaft diameter |

87mm |

87mm |

87mm |

|

Power supply |

3 phase 380 volts |

3 phase 380 volts |

3 phase 380 volts |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: lusa zhong

Mobile:+86 13829127980

Tel:+86 13829127980

Whatsapp:008613829127980

Email:sales@zsheatpress.com

Add:Fuma Road, Humen Town, Dongguan City, Guangdong Province, China