A CNC router, also known as a computer numerical control router, is a machine that uses computer-controlled movements to cut, carve, and shape various materials. It operates by removing material from a workpiece using rotary cutting tools, similar to a handheld router but with automated precision.

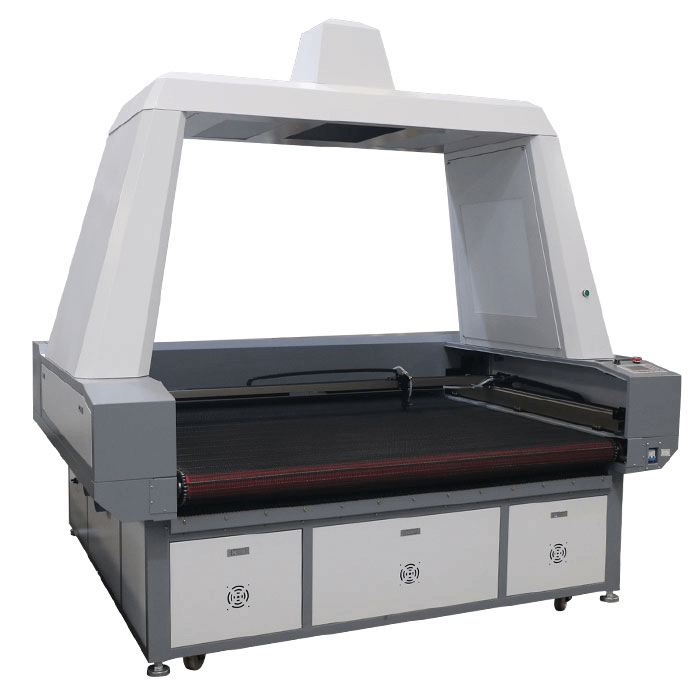

An Automatic Laser Cutting Edge Machine is a high-tech device that uses laser technology to precisely cut and shape different materials. It is equipped with automated features and advanced software that allow it to operate without human intervention.

The machine utilizes a laser beam to cut through materials such as wood, metal, plastics, fabrics, and more. The laser beam is directed by mirrors or a galvanometer system to accurately follow a pre-programmed cutting path. The machine's software controls the movement of the laser beam and adjusts settings such as power, speed, and focus to achieve optimal cutting results.

Automatic Laser Cutting Edge Machines offer several advantages over traditional cutting methods. They provide exceptional precision and accuracy, creating clean and intricate cuts with minimal waste. The laser beam is non-contact, ensuring there is no physical damage or distortion to the material being cut. Additionally, the automation capabilities of these machines enhance productivity and efficiency in manufacturing processes.

The applications of automatic laser cutting edge machines are diverse and widespread. They are commonly used in industries such as aerospace, automotive, electronics, signage, furniture, and fashion. These machines can produce complex shapes, intricate patterns, and sharp edges with ease, making them ideal for prototyping, custom fabrication, and mass production.

Overall, automatic laser cutting edge machines are a cutting-edge solution for precise and efficient material cutting, offering speed, accuracy, versatility, and automation to various industries.