A Heat Resistant Blanket is a specialized safety accessory designed to withstand high temperatures, flames, and sparks. It is typically crafted from fire-resistant materials like fiberglass or ceramic fibers and coated with a heat-resistant substance. These blankets serve multiple purposes, including fire protection, welding safety, and industrial insulation. They are commonly used in welding operations, emergency fire response, and in various industrial settings to protect workers and equipment from extreme heat and potential fire hazards. Heat-resistant blankets are crucial safety tools that provide a protective barrier against heat-related risks, ensuring both personnel and assets remain safe.

Composed of high flame retardant materials.

377*1700 377*1900 420*1700 420*1900

600*1700 600*1900 800*1700 800*1900

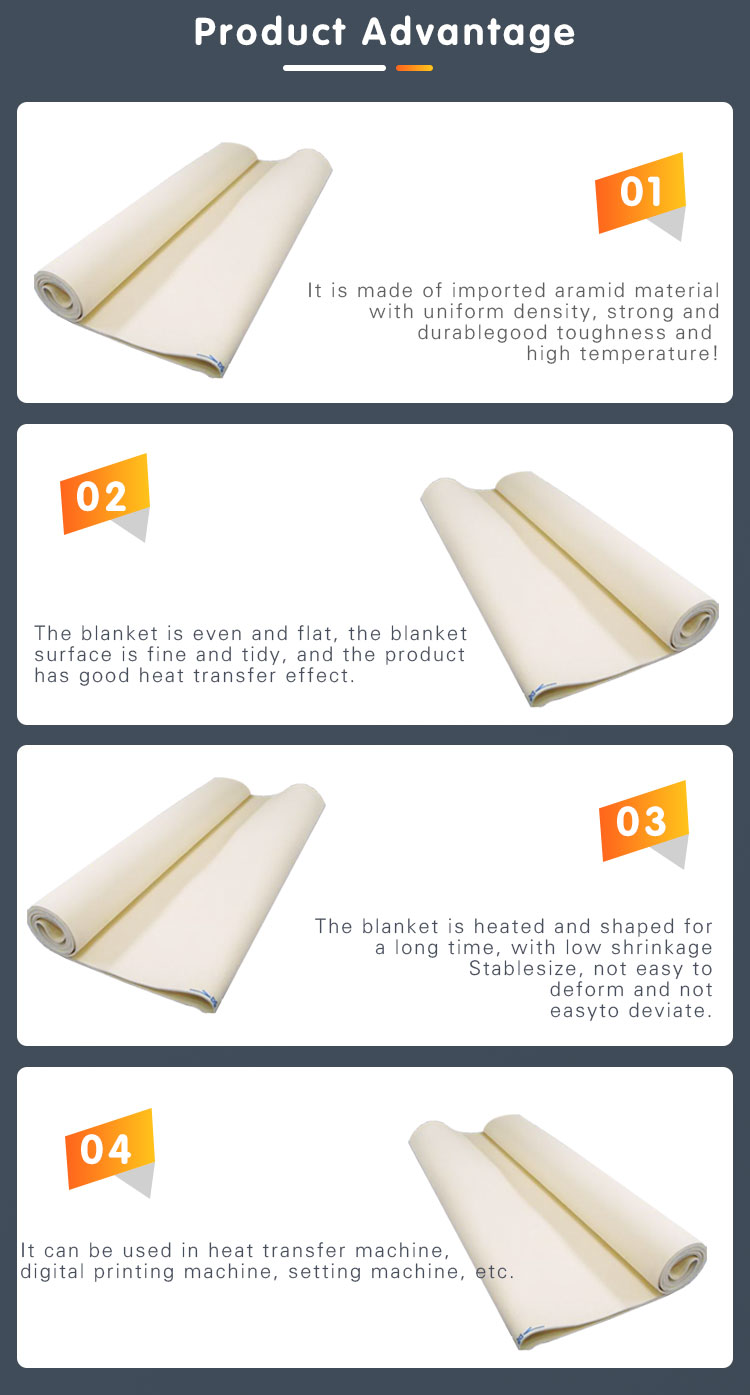

Blanket,Endless Felt(Blanket) for Heat Transfer Printing Calender nomex high temperature felt belt,felt belt for calender machine.

1.Standard Welding Blanket: These blankets often come in sizes like 6 feet by 6 feet (1.83 meters by 1.83 meters) or 4 feet by 6 feet (1.22 meters by 1.83 meters). They are designed to cover a standard welding area.

2.Fire Safety Blanket: Fire safety blankets for home use can vary in size but are typically around 3 feet by 3 feet (0.91 meters by 0.91 meters) or larger to cover a person or small fire.

3.Industrial and Custom Blankets: In industrial settings or specialized applications, heatproof blankets can be custom-made to fit specific dimensions, which can vary significantly based on the requirements.

1.Wear Protective Gear: Always use appropriate personal protective equipment, including welding gloves, a welding helmet, and flame-resistant clothing.

2.Proper Placement: Ensure the blanket completely covers the welding area, leaving no exposed surfaces.

3.Secure Attachment: Securely fasten the blanket to prevent it from moving during welding.

4.Fire Extinguisher: Keep a fire extinguisher nearby and know how to use it.

5.Ventilation: Ensure proper ventilation to disperse fumes and gases.

6.Safe Distance: Maintain a safe distance from the welding process.

7.Regular Inspection: Inspect the blanket for damage before each use.

8.Emergency Response: Know the emergency procedures and exit routes.

1. Fiberglass: Fiberglass is a popular choice due to its excellent heat resistance. It can handle temperatures ranging from 1,200 to 2,200 degrees Fahrenheit (649 to 1,204 degrees Celsius).

2. Silica Fabric: Silica fabric is extremely heat-resistant and can withstand temperatures of up to 1,800 degrees Fahrenheit (982 degrees Celsius). It is often used in applications involving extreme heat exposure.

3. Ceramic Fiber: Ceramic fiber blankets are designed to endure temperatures up to 2,300 degrees Fahrenheit (1,260 degrees Celsius). They are lightweight and have excellent insulation properties.

4. Vermiculite-Coated Fiberglass: These blankets have a vermiculite coating that enhances their heat resistance. They can withstand temperatures up to 1,500 degrees Fahrenheit (816 degrees Celsius).

5. Aluminized Fabric: Aluminized fabric blankets are coated with a layer of aluminum, providing enhanced heat reflection and protection. They are often used in proximity to radiant heat sources.

Heat resistant blankets work by providing a barrier between the source of heat and the surrounding environment. The heat-resistant materials used in the blanket are able to withstand high temperatures without melting or burning. This helps to prevent the transfer of heat, protecting whatever is covered by the blanket.

Yes, heat resistant blankets are designed to be safe to use when used according to the manufacturer’s instructions. However, it is important to handle them with caution and ensure they are properly secured to prevent any accidental fires or injuries. Additionally, it is crucial to choose a heat resistant blanket that is specifically designed for the application and temperature range you require.

Yes, heat resistant blankets can be used for emergency fire protection. They can be used to smother small fires or as a shield to protect individuals or objects from heat and flames. However, it is important to remember that heat resistant blankets are not a substitute for fire extinguishers or other appropriate fire safety equipment. In the event of a fire, always prioritize your safety and follow proper emergency procedures.

In most cases, heat resistant blankets can be reused if they remain in good condition. However, it is important to inspect the blanket for any signs of wear or damage before reuse. If there are any tears, holes, or other issues that compromise the blanket’s effectiveness, it should be replaced.

Yes, heat resistant blankets can often be cut to a desired size or shape using appropriate tools. However, it is crucial to follow the manufacturer’s guidelines and ensure that the blanket maintains its integrity after cutting. Cutting the blanket may expose raw edges, which can affect its insulation properties or increase the risk of fraying.

While heat resistant blankets can provide effective protection against high temperatures, it is important to be aware of their limitations. For example, they may not provide sufficient protection against direct flames or extended exposure to extreme heat. Additionally, certain materials used in heat resistant blankets, such as ceramic fiber, may release harmful particles when heated. Therefore, it is essential to use the blanket within its specified temperature range and always follow safety guidelines.

Yes, heat resistant blankets can be used for outdoor applications, as long as they are specifically designed and rated for outdoor use. Outdoor blankets may have additional features such as UV resistance, weatherproof coatings, or increased durability to withstand exposure to the elements.

Heat resistant blankets are not typically designed for use as building insulation. They are more commonly used in industrial settings for insulating specific equipment or components. For building insulation, it is recommended to use materials specifically designed for this purpose, such as fiberglass insulation or foam boards.

Heat resistant blankets are primarily designed for thermal insulation and heat protection, rather than soundproofing. While they may provide some degree of sound absorption, their effectiveness for soundproofing purposes is limited. To achieve proper soundproofing, it is best to use materials specifically designed for that purpose, such as acoustic panels or soundproof curtains.

Yes, heat resistant blankets are commonly used in the aerospace industry for various applications. They can be used to shield sensitive equipment or components from high temperatures and to insulate critical areas. Heat resistant blankets are often used in areas such as engine compartments, exhaust systems, or other locations where heat management is essential.