Laser cutting technology has revolutionized various industries, offering precision, speed, and versatility. Although highly effective, laser cutting can be relatively expensive compared to other cutting methods. This article explores the key factors contributing to the cost of laser cutting.

1. Equipment Costs:

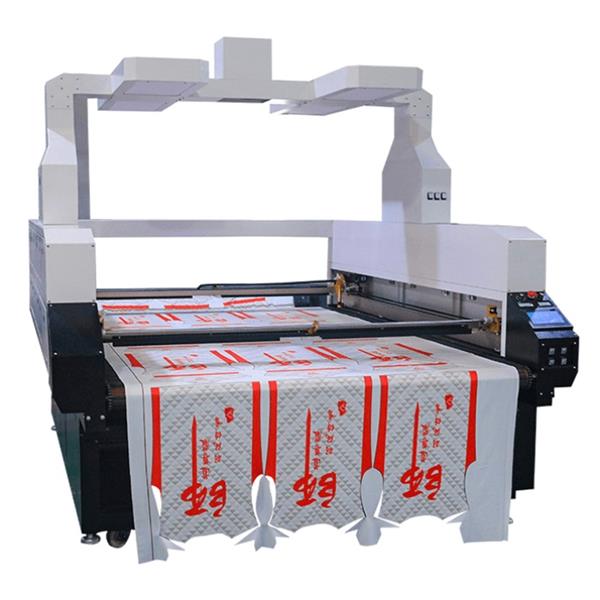

Laser Cutting Machines are sophisticated and require significant investment. The high initial purchase cost, including the laser generator, optics, computer systems, and supporting equipment, contributes to the overall expense. Additionally, regular maintenance, software updates, and operator training further add to the equipment-related expenses.

2. Energy Consumption:

Laser Cutting Machines utilize intense laser beams to melt, burn, or vaporize materials. This process requires a substantial amount of energy, increasing operational costs. The electricity consumption during laser cutting is one of the major contributors to its comparatively expensive nature.

3. Maintenance and Consumables:

Laser Cutting Machines demand regular maintenance to ensure optimal performance and longevity. Replacement of consumables like protective lenses, nozzles, and assist gas adds to the ongoing costs. High-quality consumables that ensure precise cutting and extend the machine's lifespan tend to be more expensive, impacting the overall cost of laser cutting.

4. Cutting Speed and Complexity:

Laser cutting is known for its high-speed capabilities, enabling quick turnarounds. However, intricate designs or complex cutting patterns might slow down the process, requiring more time and, consequently, increasing the costs. The complexity of the project directly affects the machine's operational hours, leading to a higher price tag.

5. Material Considerations:

Different materials exhibit various characteristics when subjected to laser cutting. Thick or dense materials, such as metals, often require more power, longer cutting times, and specialized equipment—thus raising the cost. Exotic or rare materials may also increase the overall expenses due to limited availability and compatibility challenges.

6. Safety Measures and Regulations:

Laser cutting involves working with high-powered lasers that can be hazardous if not handled properly. Strict safety measures, including interlocks, enclosures, exhaust systems, and proper training for operators, are essential for compliance with safety regulations. Incorporating these safety features adds to the cost of setting up and operating a Laser Cutter.

While laser cutting offers numerous advantages in terms of precision and efficiency, it comes with a higher price tag compared to conventional cutting methods. Factors such as equipment costs, energy consumption, maintenance requirements, cutting speed, material properties, and safety measures contribute to the overall expense. As technology advances and becomes more widely adopted, the costs associated with laser cutting may gradually decrease, making it more accessible to various industries.

Previous: What Is Fabric Rolling Machine?